Why are optimized probe sonicators critical for pharma processes?

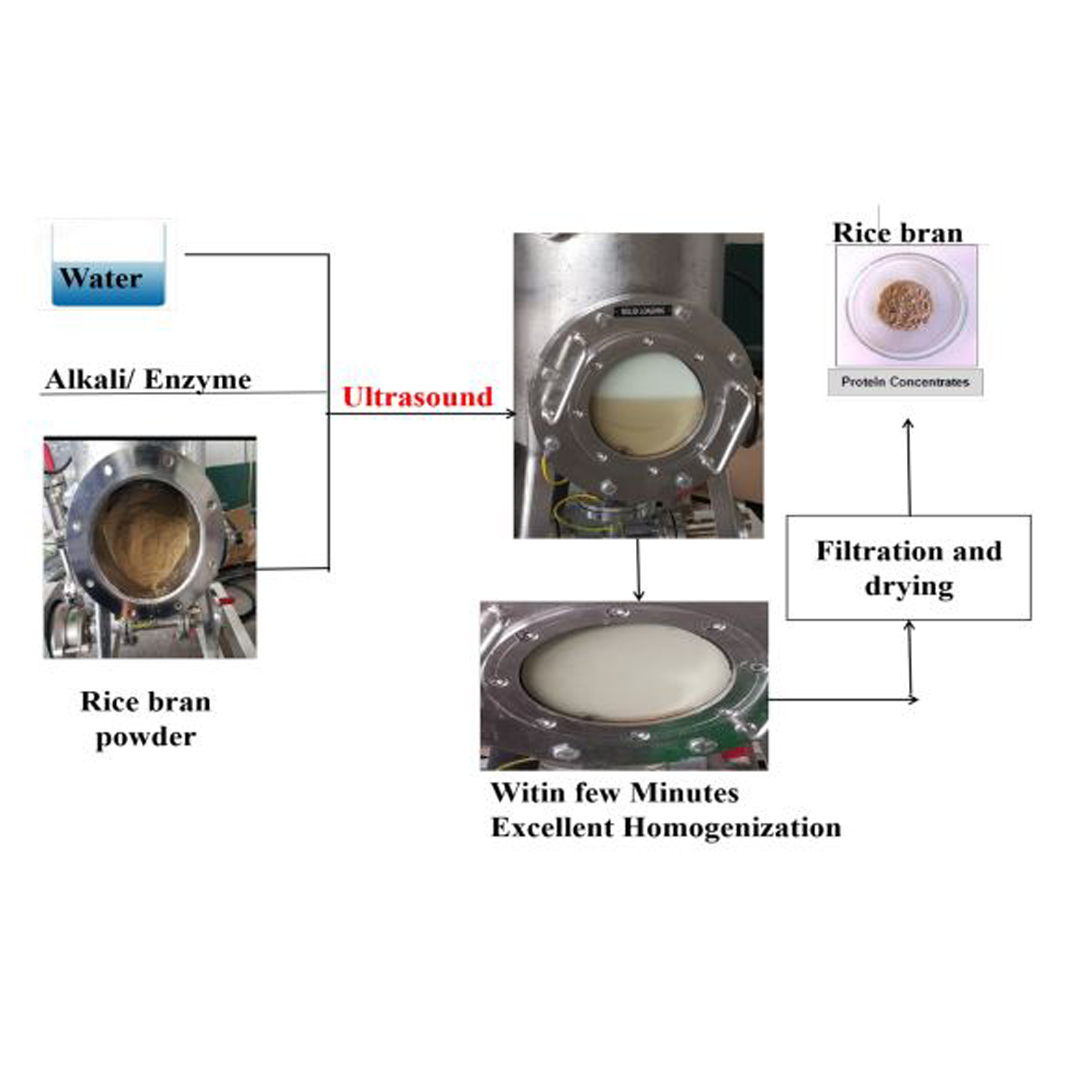

Sonication technology achieves accurate results due to the sound waves produced to agitate particles. The usage of a probe-type sonicator enables the processing of even smaller samples to meet laboratory goals. This machine can disrupt the microorganism particles used for microbiology and fermentation processes. It is a critical intensifying tool for getting stable nanofluids. The sonification is important for heat transfer in this user case. Primarily used in pharma laboratories, the ultrasoni...

- Read More.png)

.png)

.png)