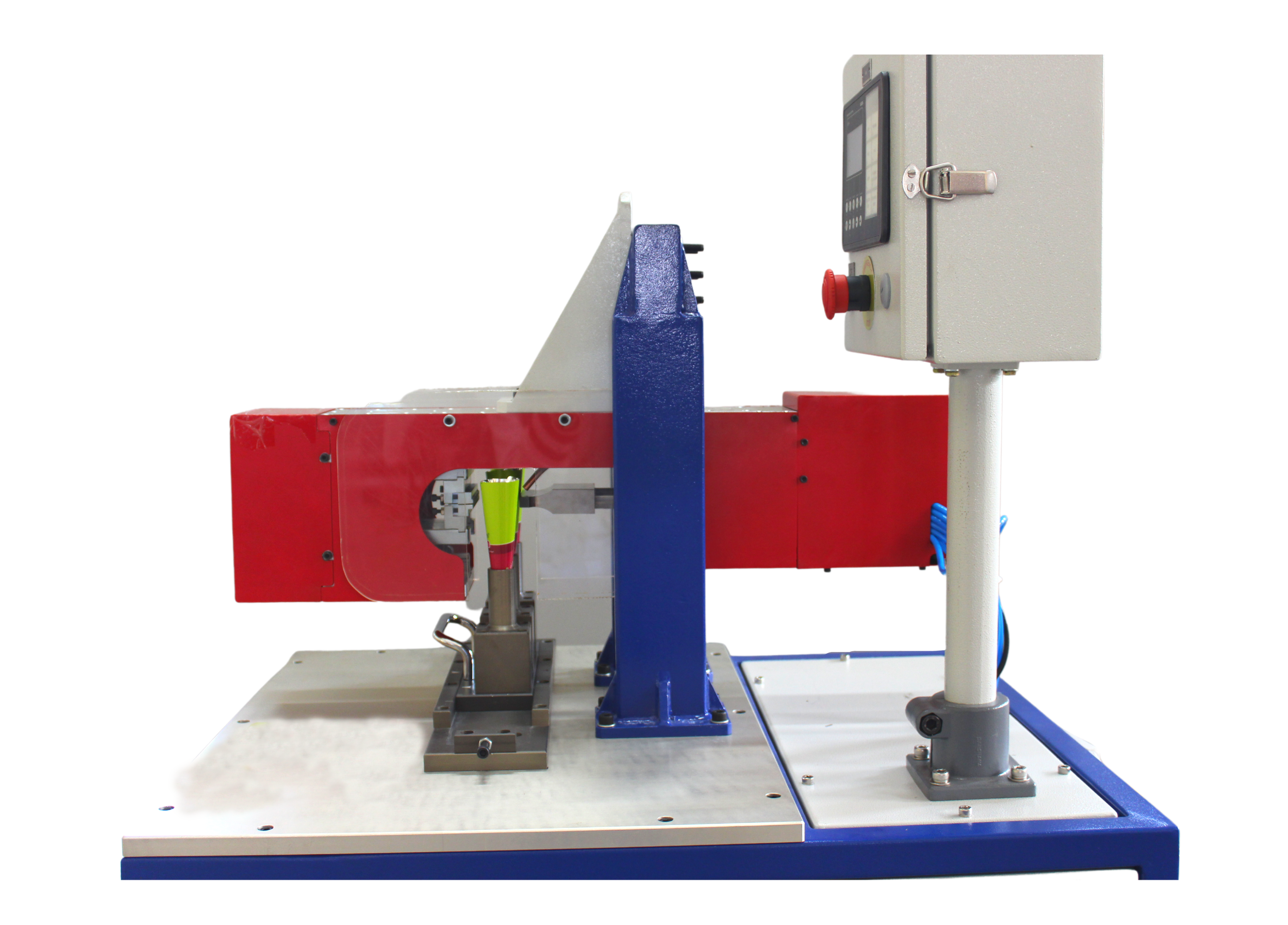

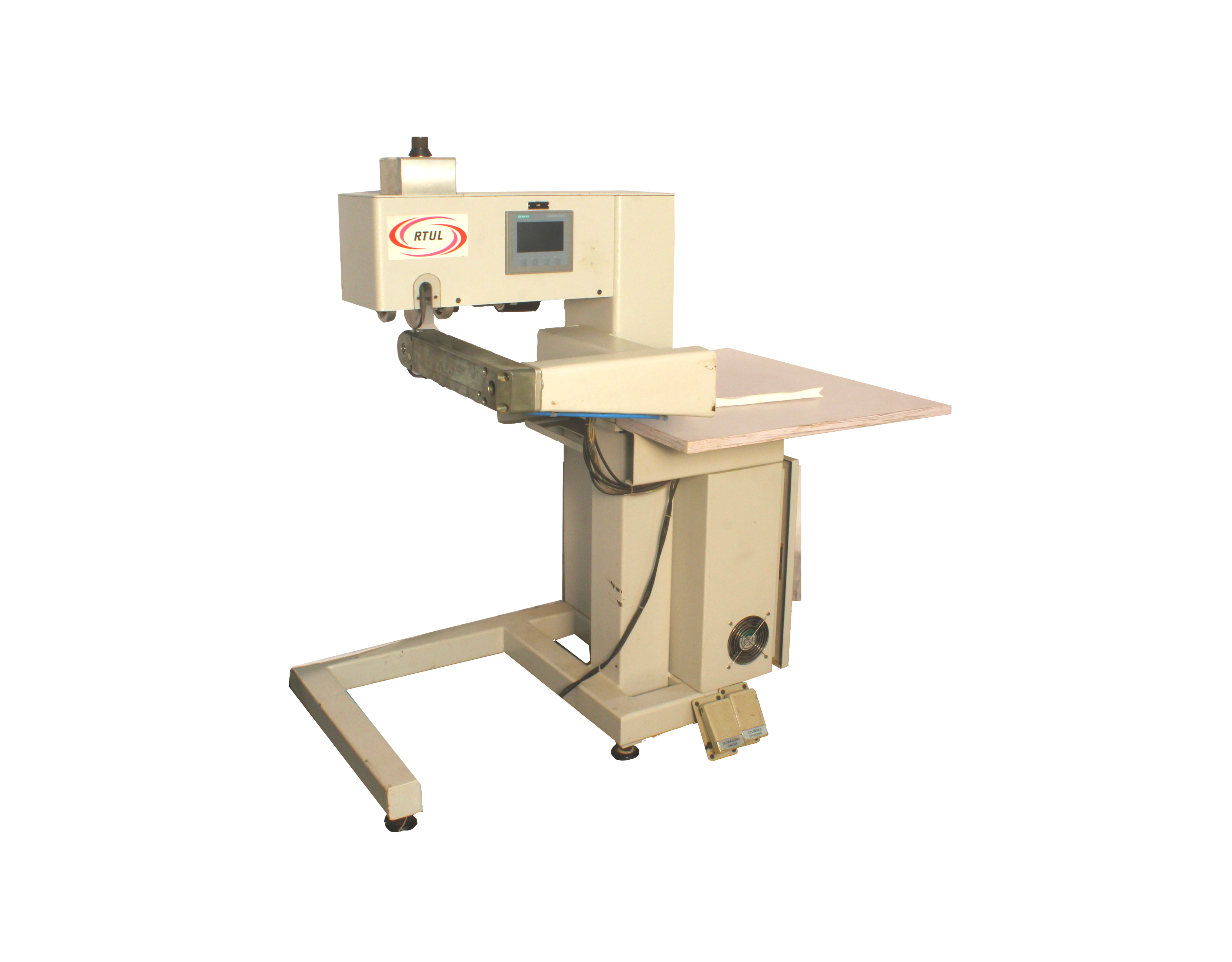

Ultrasonic Packaging Machinery

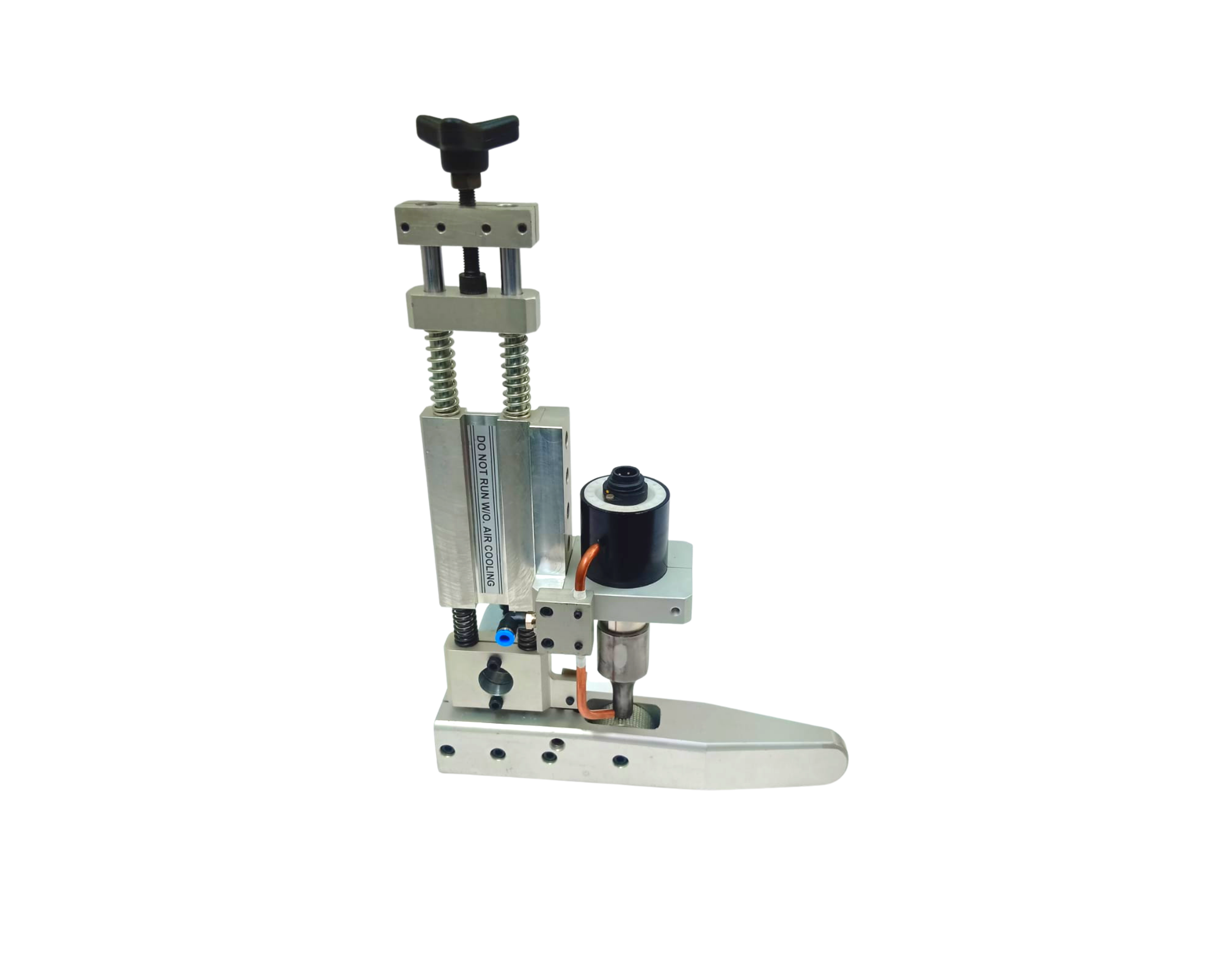

Ultrasonic Tube Sealing system is designed to be mounted as a station on all types of “inline” and “rotary” filling machines. The Ultrasonic energy is applied to the tubes present in the sealing station. Ultrasonic Sealing is a cold welding technique without heater or hot air streams making it ideally suited for cosmetics, tooth paste and pharmaceutical products.

Historically, heat sealing has been the technology used on many horizontal forms of packaging machines. Although this has become the established process for many applications, it can have its drawbacks, common issues include leakages attributed to product contamination within the seal area, coarse particles such as sugar or coffee causing puncturing, odours from trapped product, and unsightly burnt edges.

Ultrasonic welding is a reliable and economic alternative for typical thermal processes that ensures tight weld seals despite of product contamination. Ultrasonic welding technology is particularly well suited for packaging processes with high production rate requirements and applications with challenging process. The ultrasonic process also offers additional benefits such as cold welding/sealing process, tight sealing of films, repeatable and analyzable weld process which is not possible when using radiant heat process.

- Ultrasonic Power: 1000 /1500 Watts

- Frequency of Operation: 36KHz

- Diameter of Tubes: 20 to 45mm dia

- Speed of Operation: 45 to 70 tubes / minute depending on the dia and material of tube

- Air Flow: 40 CFM at 8 kg/cm2

- Mode of Operation: Constant energy / time

- Flat Pouches (Welding step by step)

- Horizontal flow pack (Continuous Welding)

- Tube Sealing (Plastic & Laminate tubes)

- Ultrasonic for HFFS and VFS

- Tea bag packaging

- Zippers

- Stand-up pouches

- Cartoon packaging

- Coffee Capsules

- Consistent sealing results of outstanding quality

- Sealing through contamination

- Cold welding/sealing process

- Reduced film consumption

- Narrow sealing seams (down to < 2.5 mm possible)

- Tight sealing of films, even if contents present in the sealing area

- Sustainable & safe

- Far fewer production faults

- Reduced maintenance costs

- Can be retrofitted on vertical and horizontal packaging machines

.png)

.png)

.png)