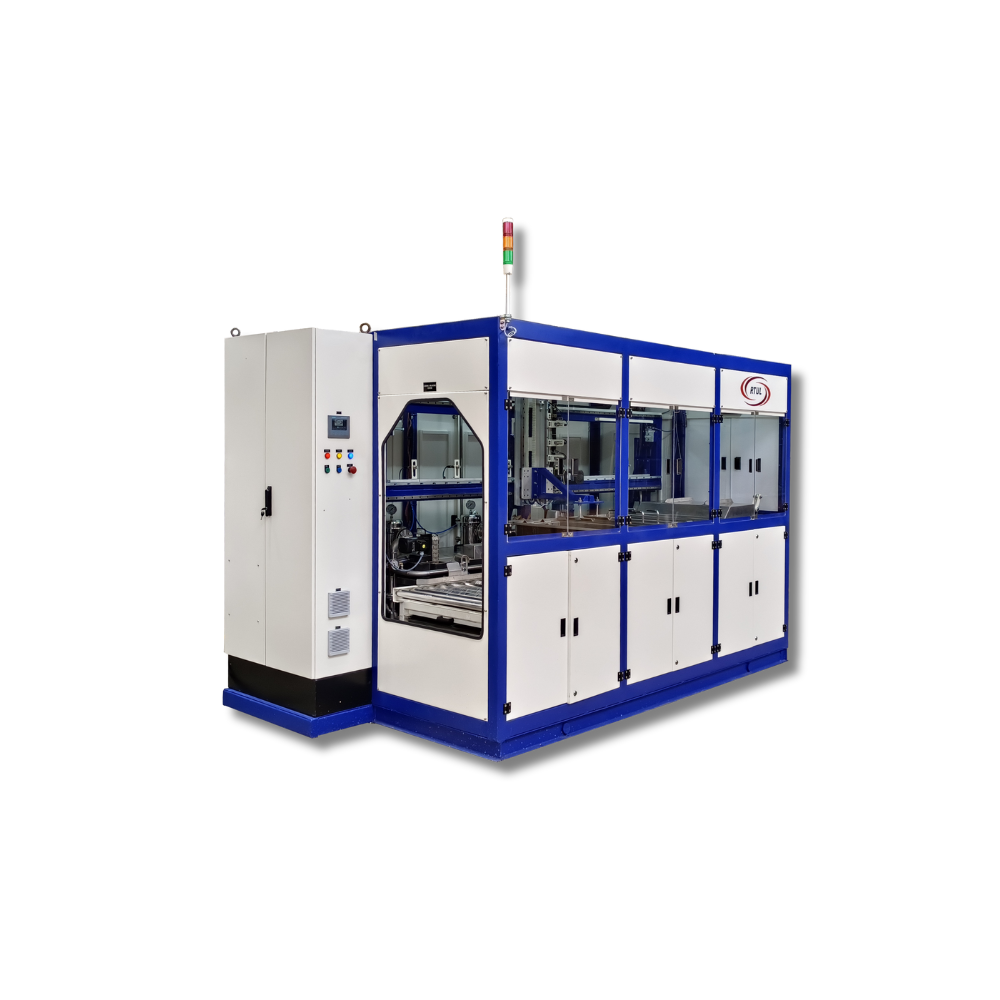

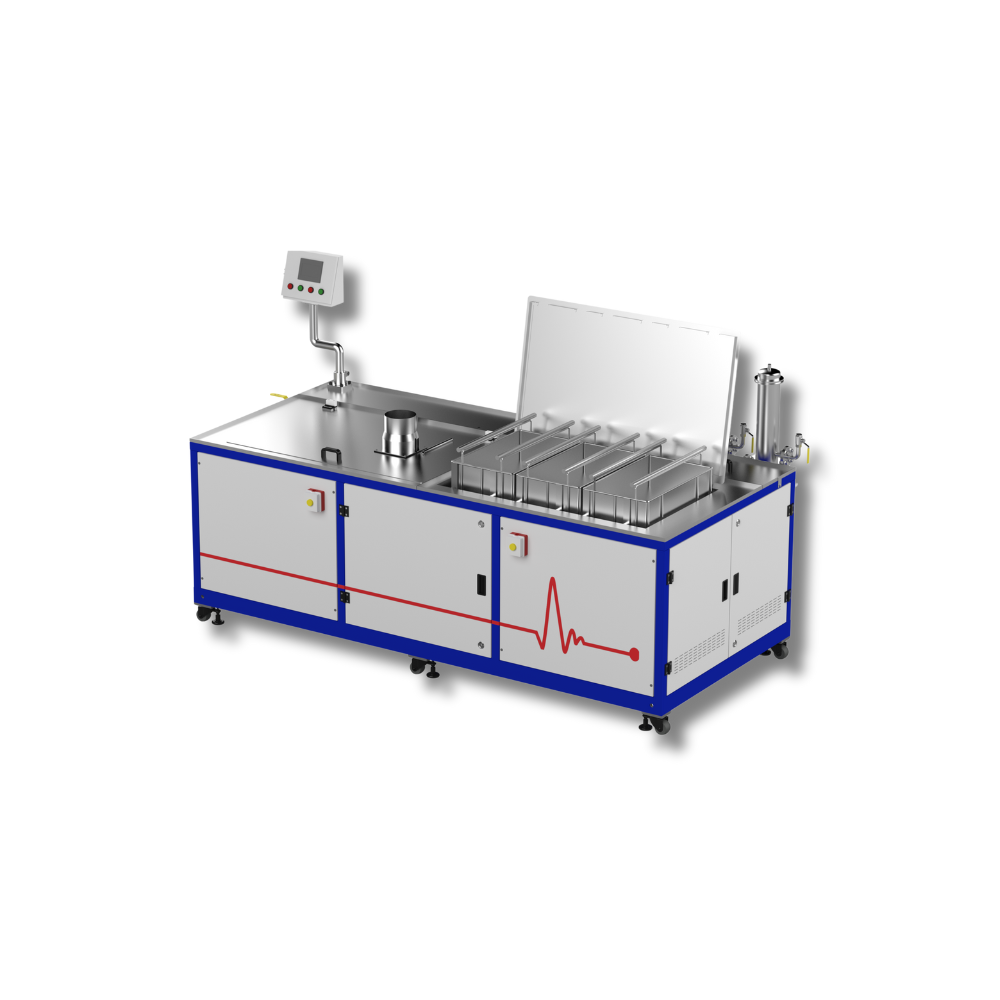

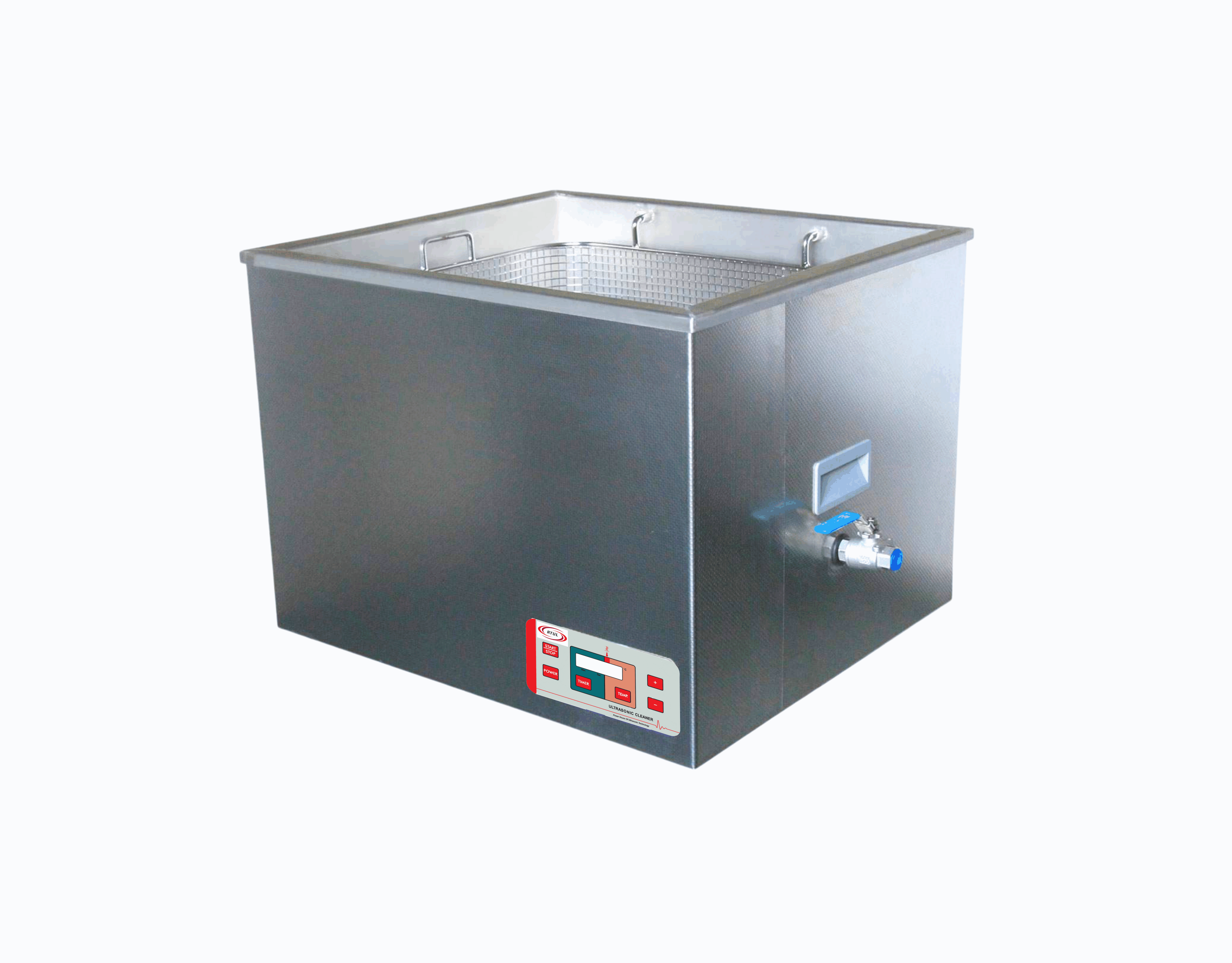

Customized Ultrasonic Cleaning Systems

High Precision Industrial Ultrasonic Cleaning Systems

Highest Cleaning Quality Through Advanced Industrial Cleaning Techniques.

Cleaning is, almost by definition, a part of any manufacturing process for the removal of sufficient surface contamination to make something suitable for the next phase of its use. It may come in at the raw material prep stage, some intermediate manufacturing stage, or prior to surface finishing such as plating or painting or before final packaging. Industrial cleaning system plays a key role during the final manufacturing stages for the cleaning of various components. Its demand has been ever-increasing as highly cleaned components are needed for various production units in reduced/less time.

This is not only to create conditions for trouble-free manufacturing but also to decide the quality and service life of the end product. The cleaning sequence depends on various aspects like type of component, material, surface quality, type of contamination, and required cleanliness level in terms of millipore as well as particle size.

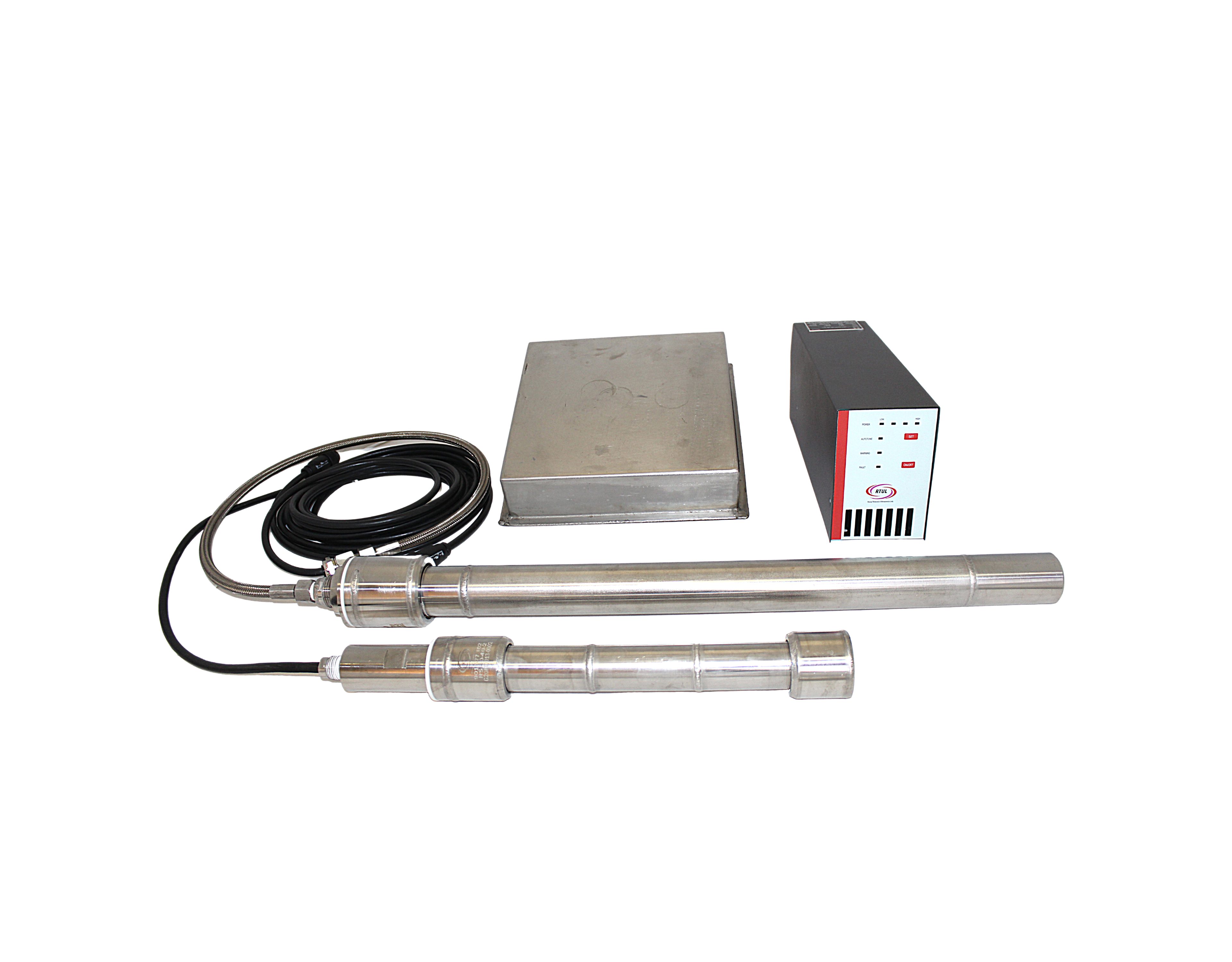

- Advanced proven TECHNOLOGY for Micro-processor controlled Ultrasonic Generators

- Options available for multiple frequencies 20/25/30/36/40/80/120 kHz

- Hi-tech components like patented tube resonators, immersible transducer box and conventional transducers used

- Many processes to choose from, including, high pressure jet cleaning, inject flood washing and turbulence

- Provided with filtration, recovery units and oil separators

- Automated material handling systems

- Well equipped lab for Millipore testing which allows selecting, recommending and designing optimum system

- Range of multi-chamber cleaners include, conveyorized ultrasonic cleaning systems, online wire/strip cleaning system, and vapor degreasing system

- Pre-cleaning

- Ultrasonic-cleaning

- Rinsing

- Anti-rust coating

- Hot air drying

- Vacuum drying

- Selection of number of stages depends upon the desired cleanliness level

- Available systems :- 3 to 10 chambers

|

- Engine block

- Cylinder head

- Fuel Injection parts

- Carburetors

- Valves

- Brake parts

- Piston & piston rings

- Steering unit parts

- Injection moulds

- PCBs

- Video heads

- Transistor leads

- Stencils

- Lenses & Glasses

- Glass moulds

- Spinnerets

- Candle Filter

- Ceramic-Nozzles

- Texturing Discs

- Spinning Aprons

- Precious metals

- Jewellery

- Watches

- Dental and Surgical Instrument

- Endoscope tubes

- Orthopedic implants

- Surgical blades

- Hypodermic needles

- Specimen slides

.png)

.png)

.png)