Ultrasonic Metal Welding

We Ensure Continuity in Conductivity.

Ultrasonic metal welding is a specialized process that utilizes high-frequency sound waves to join non-ferrous metal parts together, most commonly aluminium and copper, at a fast and efficient rate. Roop Ultrasonix Ltd (RTUL) is a leading provider of ultrasonic metal welding equipment designed to meet the needs of various industries such as aerospace, automotive, and medical.

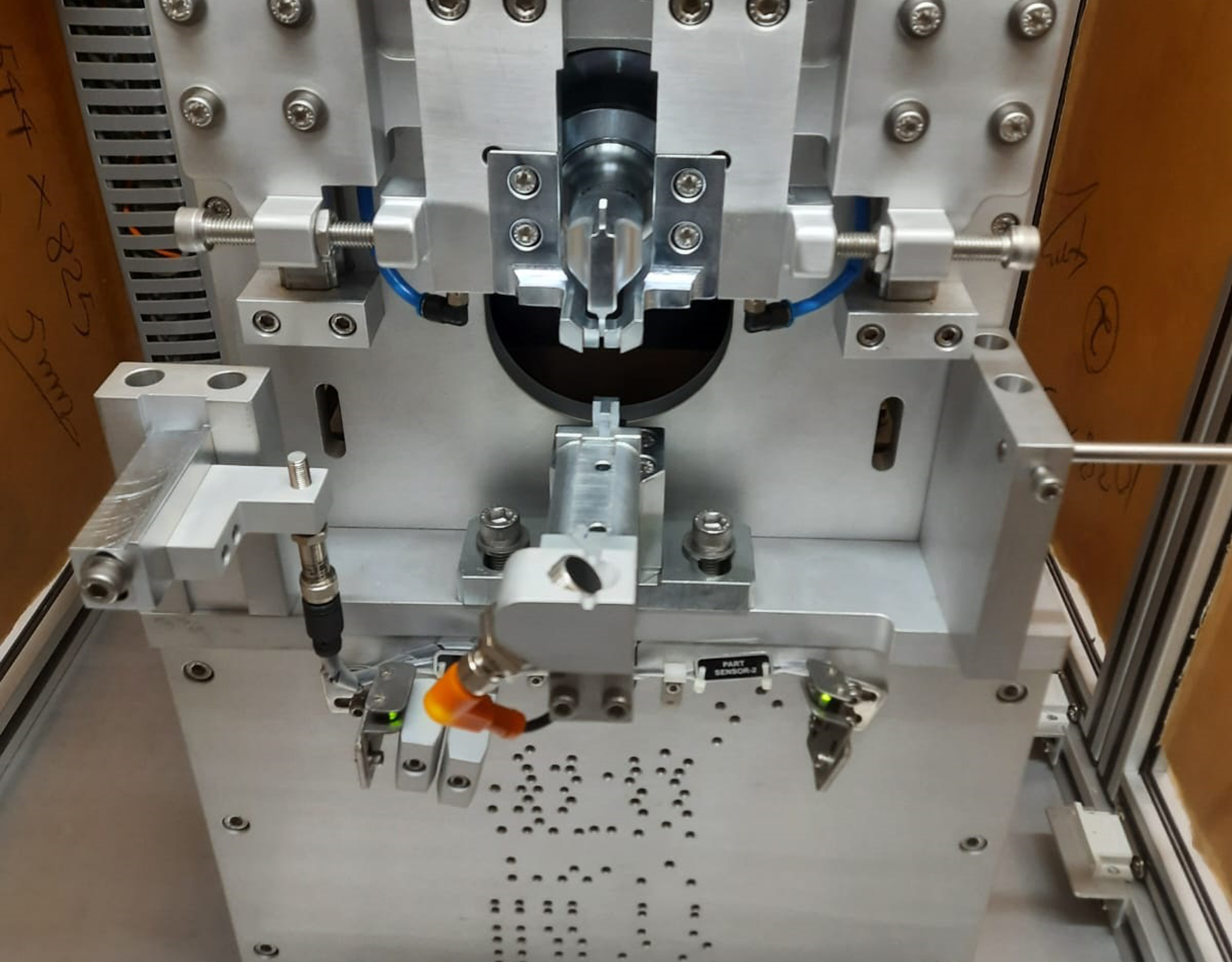

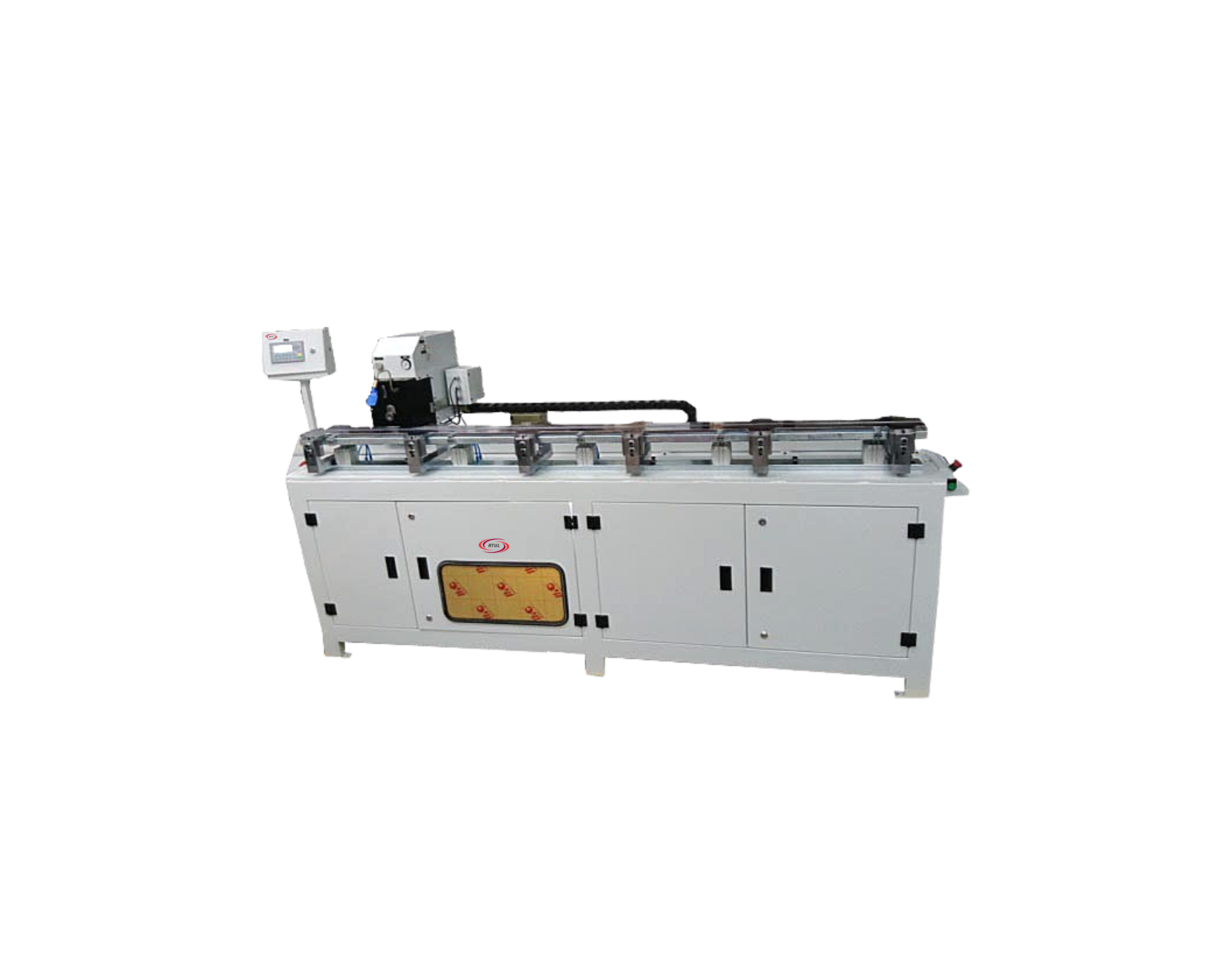

One of the key benefits of RTUL’s ultrasonic metal welding equipment is its high welding speed. The ultrasonic vibrations create a solid-state weld in a matter of seconds, making it much faster than traditional welding methods. This can greatly increase production efficiency and reduce labor costs.

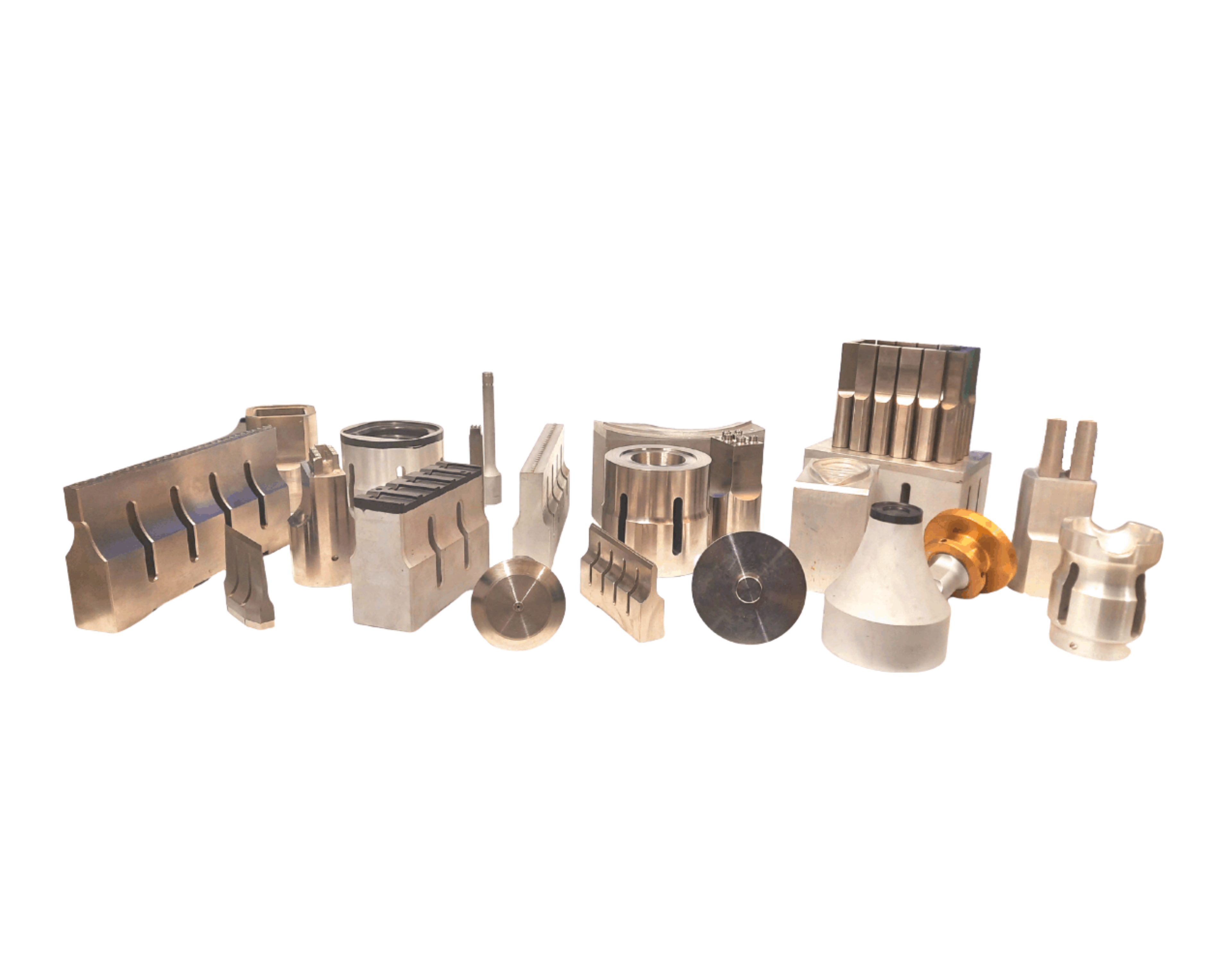

Another advantage of RTUL’s equipment is its versatility. The equipment can be used to weld a wide range of non-ferrous metal types including aluminum, copper, and other non-ferrous alloys. It can also weld parts with varying thicknesses, making it suitable for a variety of applications.

Precision is also an important factor in ultrasonic metal welding. RTUL’s equipment offers precise welding that is essential in ensuring the components withstand the high thermal and mechanical loads in the applications. The precision of the weld is critical in industries such as aerospace and medical where high precision is a must.

In addition, RTUL’s ultrasonic metal welding equipment is also equipped with various features to ensure the process is easy to operate and maintain. These include automated welding cycles, adjustable welding parameters, and real-time monitoring of the welding process. The PLC control system allows the user to program and monitor the welding process.

In conclusion, ultrasonic metal welding is a specialized process that offers high speed, precision, and versatility in joining non-ferrous metal parts together. Roop Ultrasonix Ltd (RTUL) is a leading provider of ultrasonic metal welding equipment designed to meet the needs of various industries and offers features to ensure the process is easy to operate and maintain. The equipment’s high welding speed, precision, and versatility make it an ideal solution for various applications in the aerospace, automotive, and medical industries.

- Non-Ferrous metals

- Ceramics & metal coated materials

- Solar Tube & Fin Welding

- Ultrasonic Rotary Head

- Alternator Collector

- Plastic Coated Aluminium Tube

- Lithium Ion Battery

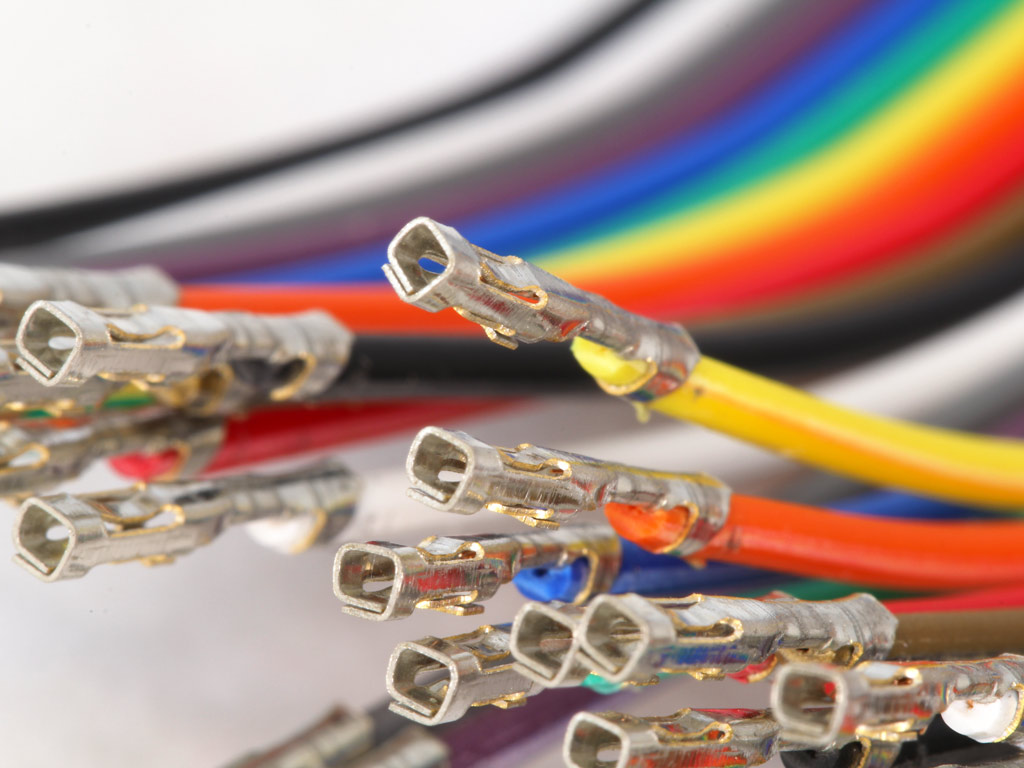

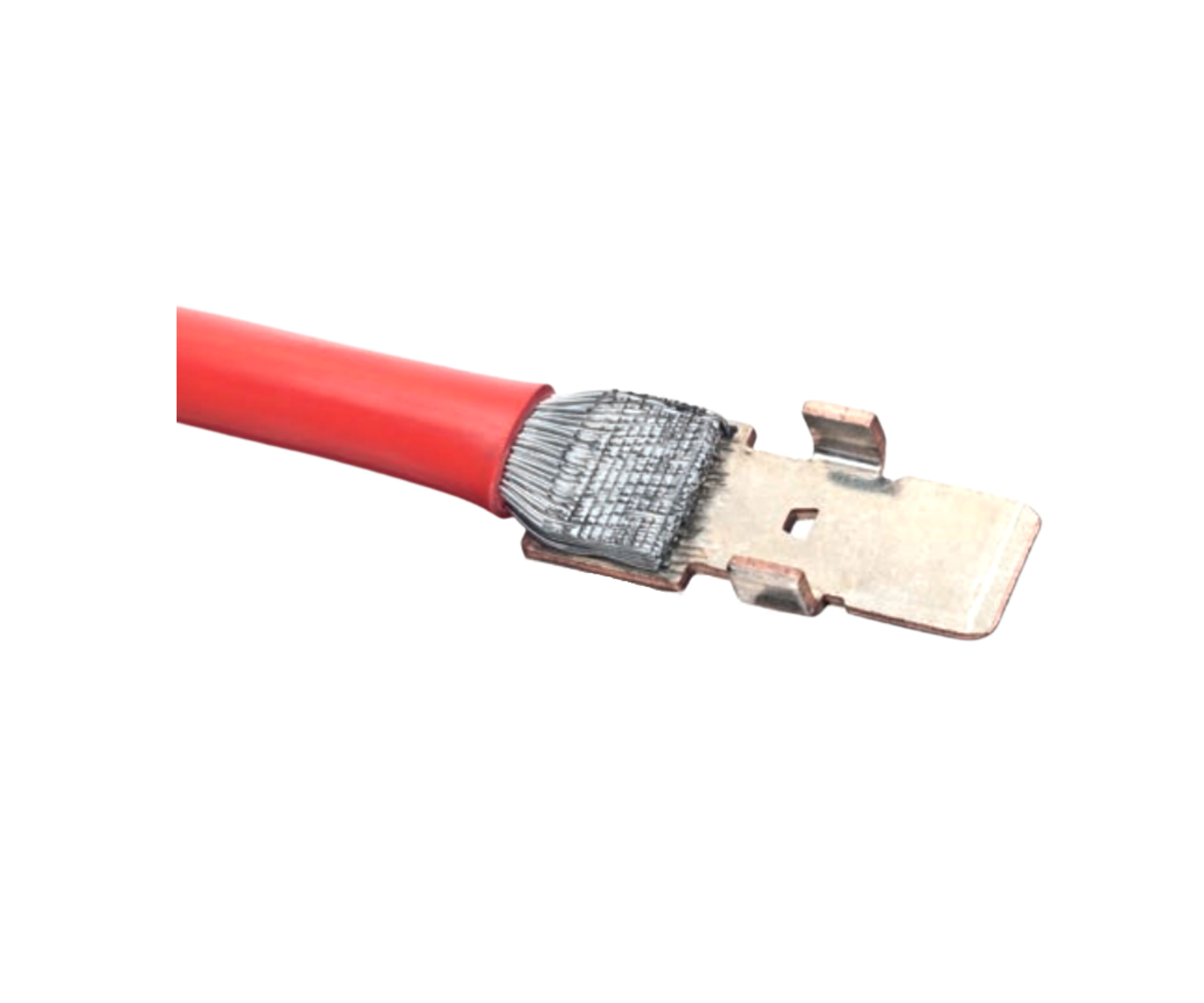

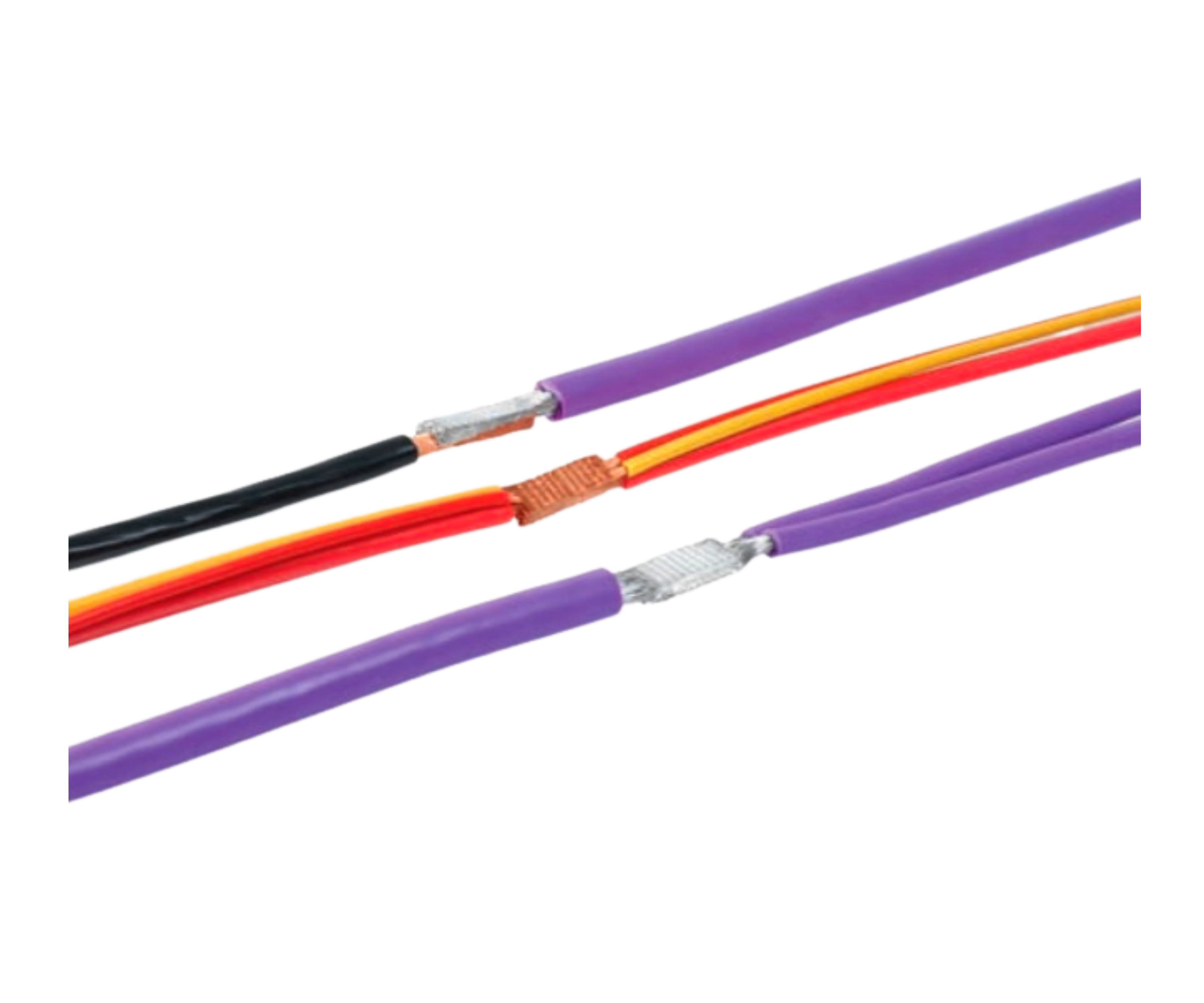

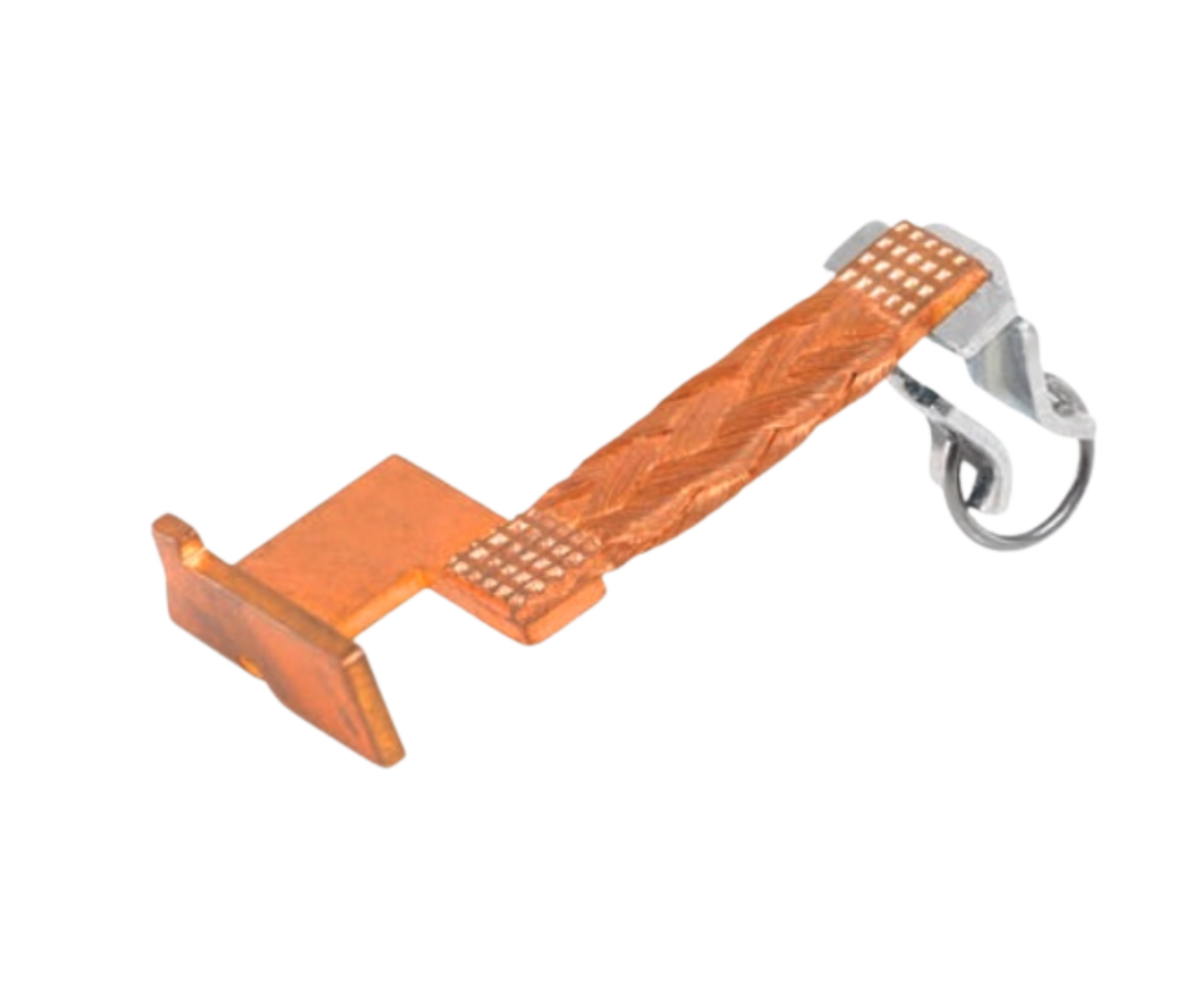

- Wire Termination

- Flexible Wires Into Terminal

- Typical Torsional Applications

- Direct joining of materials with dissimilar properties

- Very short welding times (fractions of seconds)

- Low heat generation in the welding joint

- Strength in the joints close to the base materials

- No additional joining material required

- Low thermal and electrical transfer resistance

- Can easily be integrated into automatic production lines with options for welding parameter recording / quality control

- Cold welding technique with temperatures of approx. 30-40 % below melting temperature

- Breaking up of oxide skin and flattening of surfaces until atomic bonding forces come into effect

- Diffusion of different materials with each other within fractions of seconds

- Optimum strength since no micro structural changes occur in the boundary layer

- Helium tight metallic joints

.png)

.png)

.png)