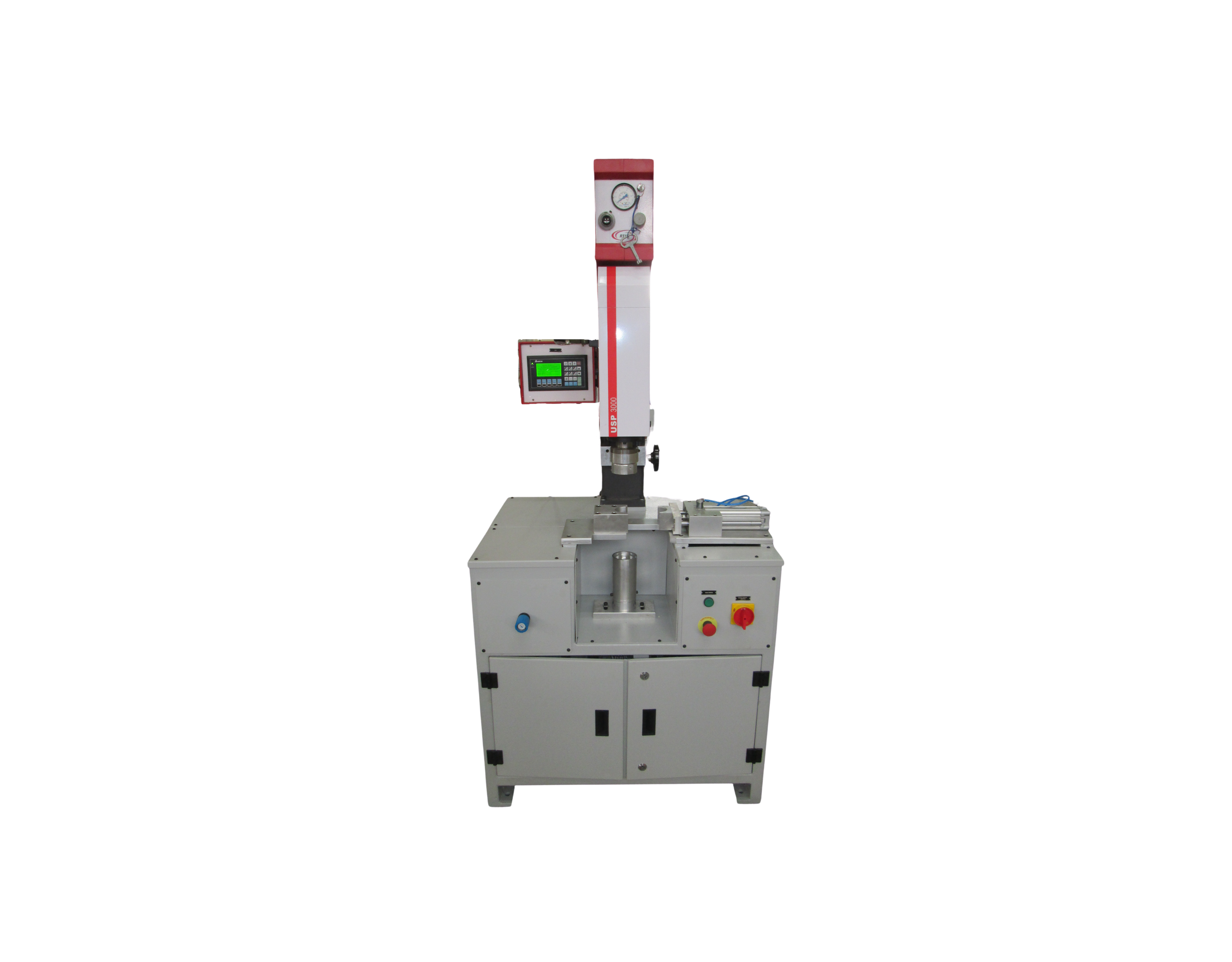

Spin Welding Systems

Spin Welding Machine – A Total Solution For All Your Circular Thermo Plastics Assembly

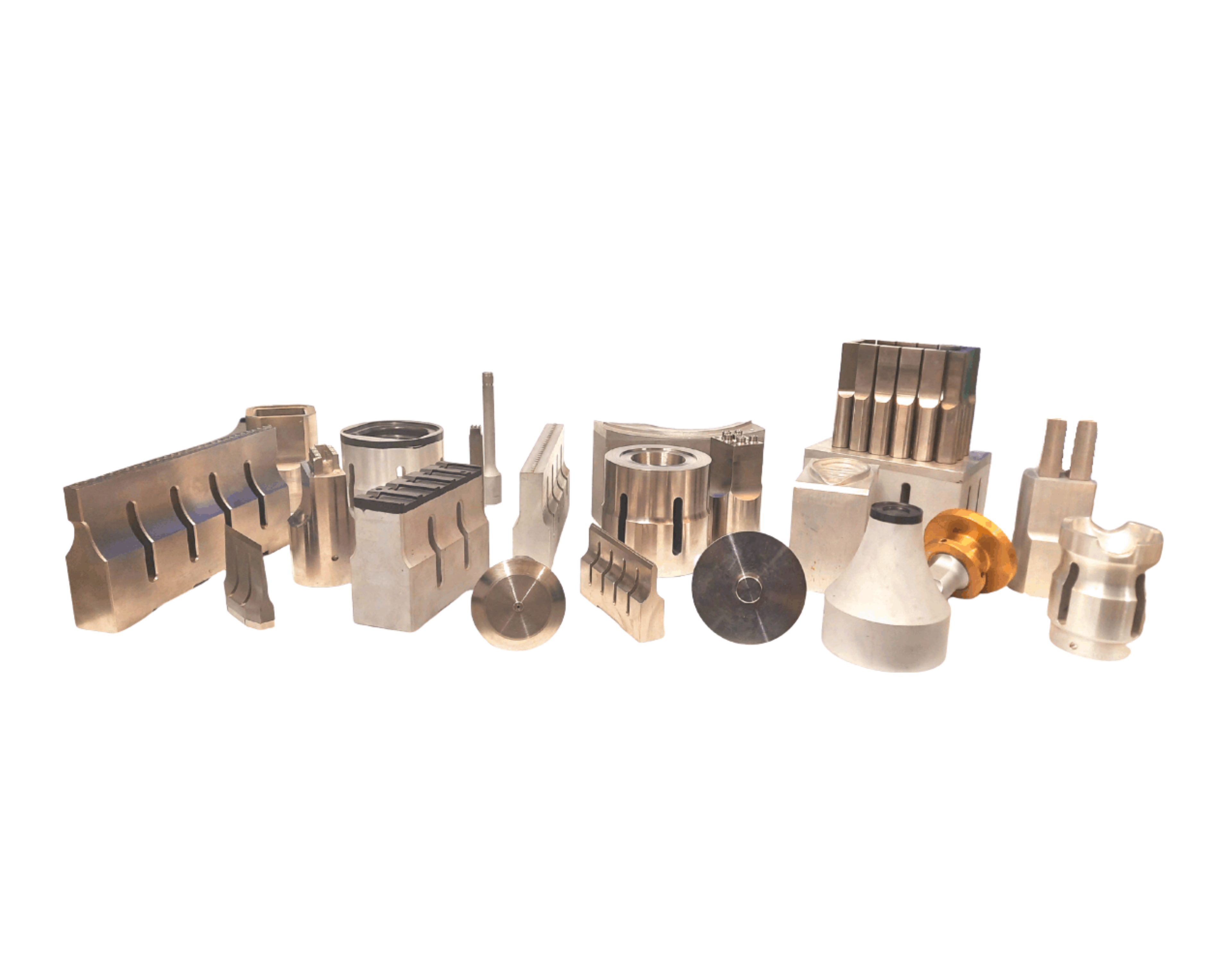

Spin Welding as the name implies, is a friction welding technique to join thermoplastic parts. It is essential the parts to be joined or atleast their joint areas must be circular for this method. A shallow Machining groove (tongue & groove) is desirable to index the two parts and to provide a uniform bearing surface.

With one part held stationary, either vertically or horizontally in a special fixture, the other is rotated at 100-4000 rpm with enough pressure applied to keep the parts in contact with each other. The heat generated in friction is used to bring the surfaces to a sealing temperature. When sufficient melt is obtained, the spinning stops, and the pressure is increased to distribute the melt and also to squeeze out excessive melt, completing the general process.

- Stroke length - 100mm.

- Controller - PLC with suitable MMI.

- Time setting - Three time setting for delay (T1), activation (T2) & cooling from 0 to 9.99 sec.

- Power - 1KW / 2.5KW / 4KW / 5KW.

- Speed of motor - 100 to 4000 rpm.

- Pneumatic press - Upto 2500 N.

- Weight - 120 Kg.

Input

Power Supply 3 phase , 415 V

Pneumatic Air 6-8 bar

Output

Servo Drive 3 / 4.5 / 6.5 kw

Servo Motor Panasonic

Maximum RPM 2500

Mechanical Data

Max. part dia. To be weld Ø 300 mm

Vertical Stroke 100 mm

Maximum Throat 250 mm

Tool Locking Collect Ø 22 mm

Table Height 950 mm

Overall Dimensions 900 mm x 700 mm x

2000 mm ( appx.)

Control

Stroke 10 to 100 mm

Spinning RPM 500 to 2500

Spinning Time 0.01 to 9,99 sec.

Location Accuracy ± 0.1* degree

(Subject to molding locator

accurcy)

Part Locking Through Fixture

PLC Control Delta

Operating Panel Hi-Tech MMI- Inbuilt

Welding Mode Revolution / Time Mode

Welding Pressure Regulator Festo, precision Regulator

Welding Depth Sensitivity (Optional)

Pressure Switch (Optional)

Safety Curtains (Optional)

Canopy (Optional)

- Any circular part made out of Thermoplastics specially for Nylon,

- PP & Polyethylene Group

- Cream Jar

- Hair Oil Bottle

- Container Lid

- Casserole

.png)

.png)

.png)