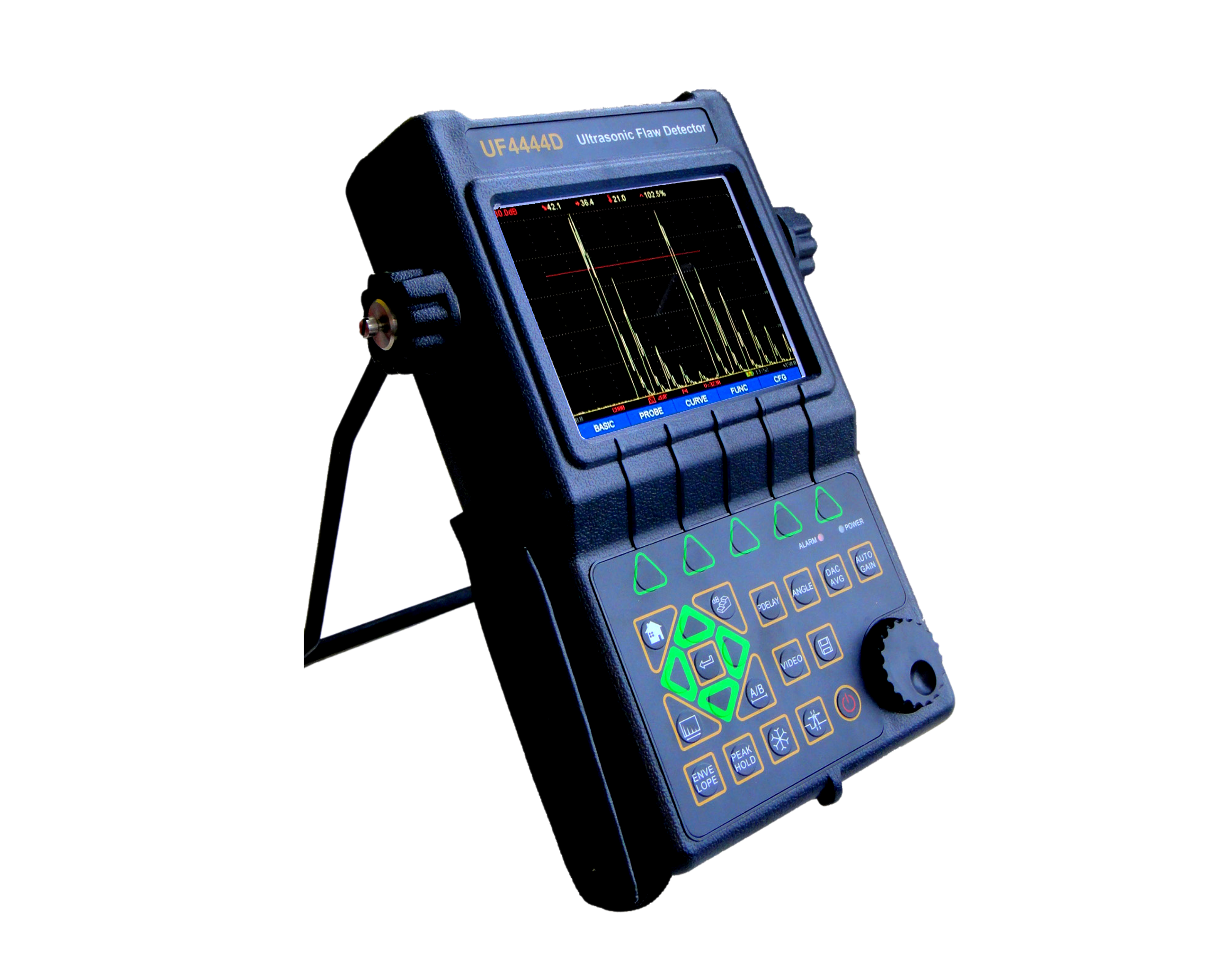

Ultrasonic Flaw Detector

Among the non-destructive testing methods for internal defects, Ultrasonic testing is the fastest and most reliable method. With this one can save on material, labor, machine cost & time, by early detection of defects at the raw material stage.

RTUL’s Portable Ultrasonic Flaw Detectors provide a very user-friendly flaw detection technique to analyze blow holes, porosity, inclusion & any types of flaws.

Ultrasonic Flaw Detectors have high-frequency sound waves generated by piezoelectric transducers that enter the object to be tested and get reflected at the interphase of defects such as cracks, blow holes, inclusions, porosities, lack of bond, etc. The reflected echo is displayed in the form of peaks on the screen of Ultrasonic Flaw Detectors. The amplitude and position of these peaks give useful information regarding the location, shape & size of the defect.

UFD 4444D is an advanced model with the latest electronics, TFT display & features like DAC, and AVG useful in complex ultrasonic testing applications. Video mode, A scan freeze, B scan & PC connectivity in model 4444D. Portable light in weight and user friendly which meets international standards. Dual gates with positive/negative logic and threshold setting with alarm & wide band amplifier. Auto & quick calibration is available in all the models.

- Bright High Resolution TFT Display.

- Light Weight & Easy to use.

- DAC with Alarm.

- RF output.

- B – Scan

- Video Mode.

- Dual Gate.

- USB Port.

- A Scan Freeze.

- Battery Life: 8 hrs.

- For Casting

- Forging and rolled products

- Weld inspection

- Bond testing

- Automatic immersion testing for tubes and rods

- Research and laboratory studies

- Nodularity Monitoring/Measuring.

- Elastic Constant Measurement.

- Single Channel Multiplexing online testing.

- Multi-channel on line testing.

- Velocity measurement in gases i.e velocity based gas analysis.

- Range: (0~9999) mm

- Bandwidth: (0.5~15) Mhz

- Material Velocity: (1000~9999) m/s

- Dynamic Range: ≥32db

- Vertical Linear error: ≤3%

- Horizontal Linear error: ≤0.2%

- Sensitivity Leavings: 140 ± 3db

- Rejection: (0 to 80)% Linear

- Noise Level: ≤10%

- Ambient Temperature: (-20~50)°

- Relative Humidity: (20~95)% RH

- Overall Dimensions: 263×170×61 (mm)

- PC Connectivity: USB 2.0 High Speed Communication Port

.png)

.png)

.png)