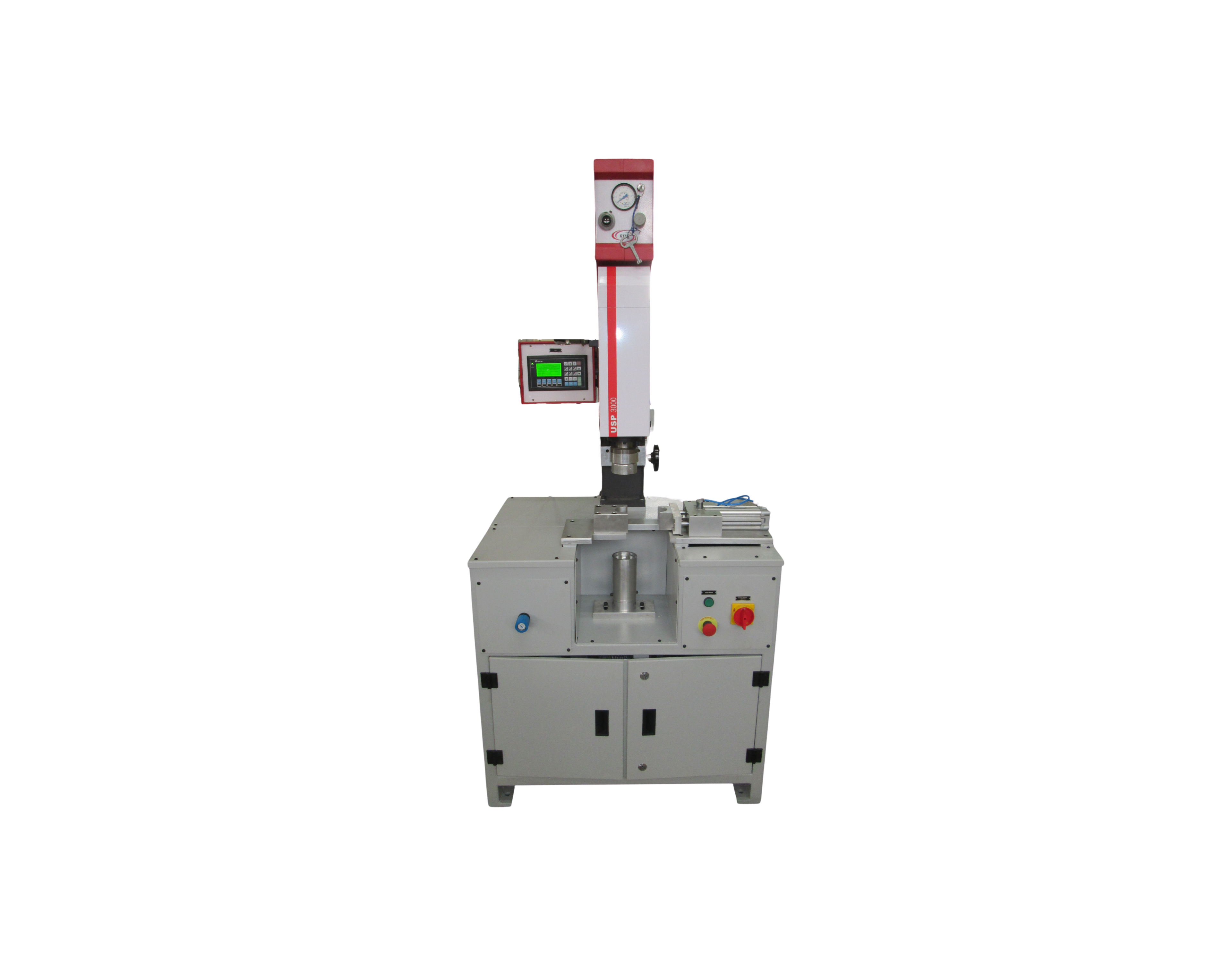

Ultrasonic Presses

REDEFINING THE LIMITS OF WELDING

As a joining process for industrial thermoplastics, the ultrasonic method is very well-proven in practice. Particularly in the production of mass-produced parts, the process offers a definite advantage over previous methods.

RTUL offers a wide selection of welding equipment and installation which with respect to generator performance, range of welding force, frequency of operation, and possible uses, efficiently satisfies your specific application requirements.

Each ultrasonic welding installation comprises the following main components:

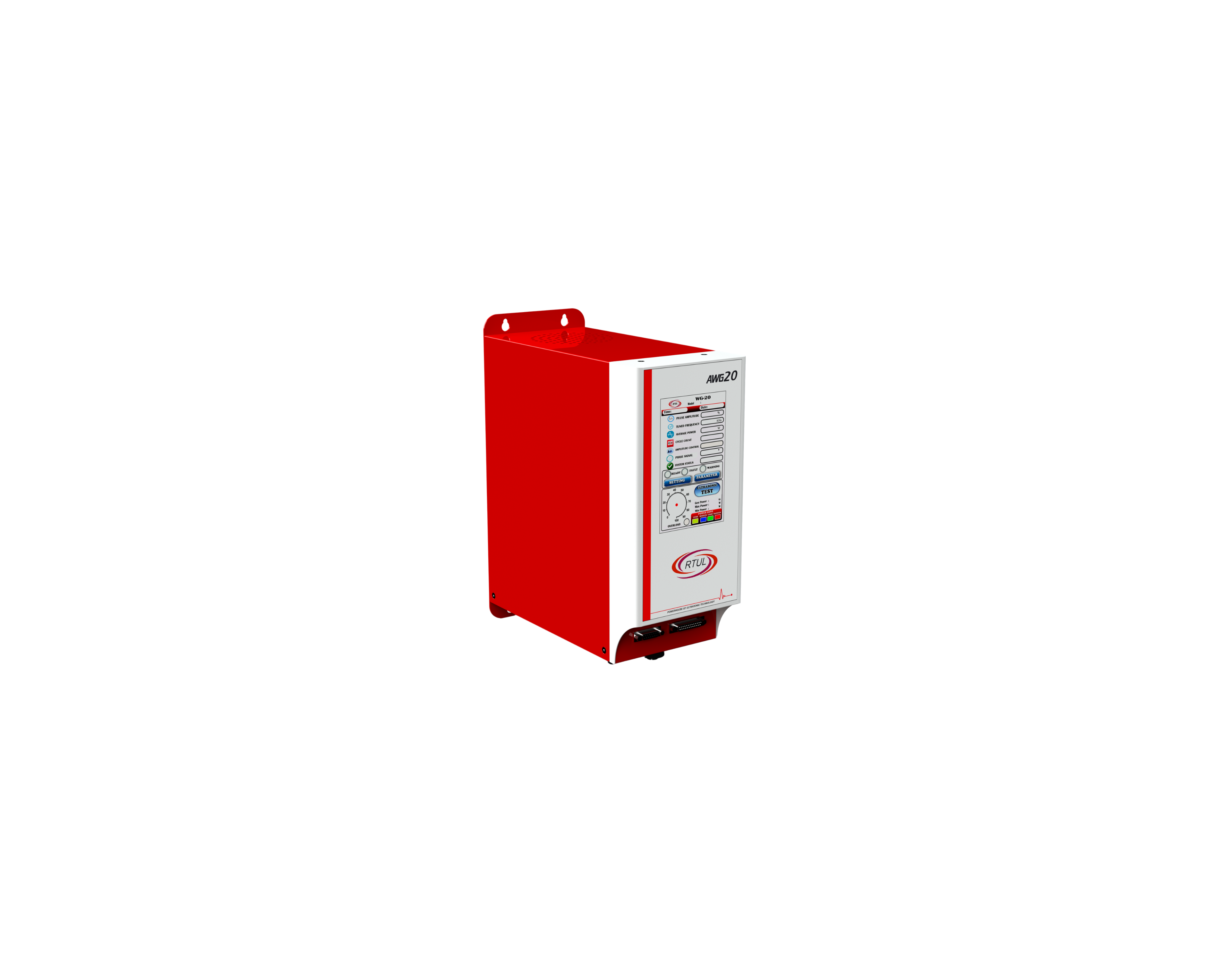

- Electronic Ultrasonic Generator

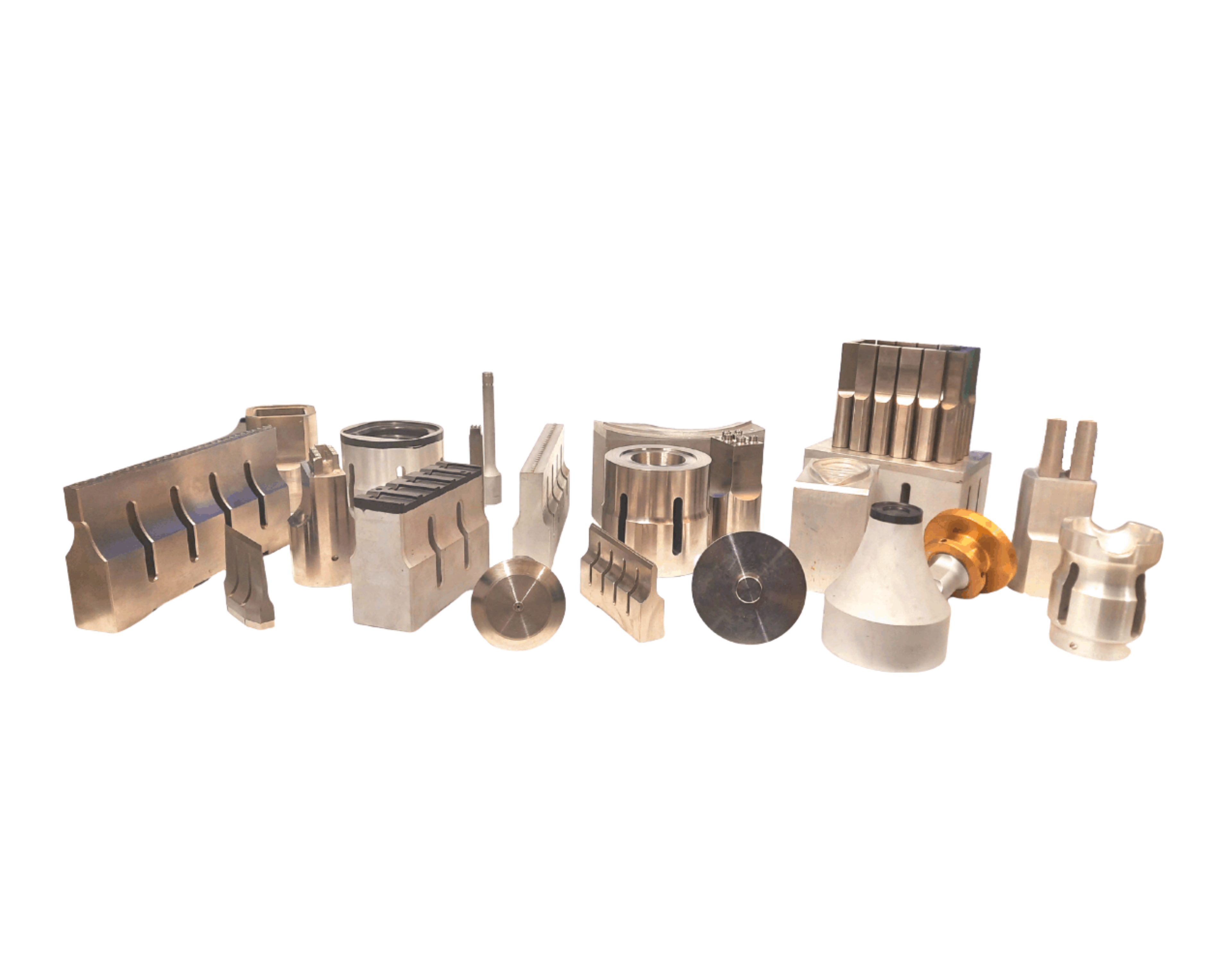

- Transducer, Booster, and Sonotrode

- Pneumatic Press and Control Unit (AWC 6 & MPS 3.1)

The Generator is the heart of every ultrasonic welding system, its function being to supply the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical/ultrasonic vibrations which are finally transmitted via, the booster and sonotrode to the item being welded.

|

UHG 500/1000 |

WP 10/500/1000 |

WP 750 |

WP 3000/1000/1500/ 2000/3000/4500 |

WP 3000/6000-3000/4500 |

|

|

Pneumatic Press |

WP 450 |

WP 750 |

WP 3000 |

WP 3000 |

|

|

Closing Force Max. |

– |

450 |

750 |

3000 |

3000/6000 |

|

Generator |

HG-35-500/1000 |

WG-35-500/1000/M |

WG-36-1000/WG-20-1500W |

WG-20- 1000/1500/ 2000/3000/4500 |

WG-15-3000/4500 |

|

Ultrasonic O/p Power (W) |

500/1000 |

500/1000 |

1000/1500 |

1000/1500/ 2000/3000/4500 |

3000/4500 |

|

O/p Frequency (KHz) |

35 | 35 |

20/36 |

20 | 15 |

|

Dimention- Press |

Dia 54×220 |

300x500x490 |

360x575x1000 |

410x685x960 |

410x685x960 |

|

(WxDxH)mm Generator

|

500x350x220 |

93x365x278 |

510x440x220 |

510x440x220 |

510x440x220 |

|

Weight Press

|

0.6/1.2 |

22 | 60 | 100 | 100 |

|

(Kg) Generator

|

15 | 7.2 | 35 | 35 | 35 |

|

Max. Stroke (mm)

|

– | 50 | 100 | 100 | 100 |

|

Throat Depth (mm)

|

– | 80 | 150 | 275 | 275 |

|

Working Table (WxD)mm |

200×300 |

300×325 |

465×410 |

465×410 |

- 7" Colour touch screen.

- Provides 4 different Trigger modes - Time, Force, Distance and Touch.

- Provides 5 different weld modes - Time, energy, Weld Distance, Absolute Distance and Maximum Power.

- Energy, Distance Measurement and control.

- Variable pressure profile for more accurate Weld Results.

- Amplitude Profile to weld Few Semi- Crystalline Materials.

- Automatic Saving of last 99999 welding Results.

- User can store 50 different Job Settings. (Data set management)

- Selectable calibration pulse for Automatic Sonotode Frequency Tuning.

- 6 Types of different quality windows

- RS-232/USB Interface for receiving Welding summary on PC.

- In-built Rotary Table Interface with Two Sensor Support.

- In-built Pick and Place System Interface.

- Provides 4 User Programable Inputs and Outputs.

- Modular design of system allows easy capacity up-gradation.

- Precise time setting with least count of 0.001 second, thus avoiding over welding, deformation, reduction of production rate and excess consumption of power.

- Additional ultrasonic vibration at the end of cycle resulting into removal of particles from horn.

- Self diagnosis-Microprocessor allows operator to rectify the system.

- Automatic tuning of horn & horn life indication, easy capacity upgradation, amplitude setting without changing the booster.

- Energy mode option in addition to time mode allowing precise setting of energy as per job requirement.

- Automobile

- Clock / Watches

- Cosmetics

- Domestic Appliances

- Drawing Equipment

- Electronics Equipments

- Energy Meters

- Furniture

- Lighting Equipments

- Mechanical Enggineering

- Medical Equipments

- Office Equipment

- Optics

- Photography

- Precision mechanics

- Pump

- Radio-Tv

- Sound-Radio-TV

- Sports goods

- Surgical

- Telecommunications

- Textiles

- Teaching aids

- Toys

- Video

- Zip fasteners & Many more

.png)

.png)

.png)