Manufacturers require ultrasonic cleaning machines to keep equipment in a hygienic condition. Powerful cleaning mechanisms are essential to maintain production quality and continuous productivity. These devices sterilize wide-ranging materials like precision instruments, F & B equipment and even carburettors. Ultrasonic cleaning components work faster compared to traditional methods of decontamination. Being inexpensive, they are suitable to clean cavities and crevices of industrial equipment which are hard to reach.

RTUL Group is in the business of supplying a range of ultrasonic cleaning equipment for different industries. The wave-effect frequency of cleaning components makes it an ideal companion for quality control managers or supervisors in the plant.

This post explains the main parts of an ultrasonic machine and how it produces the mechanical effect with frequencies for eradicating contamination.

Bifurcation of cleaning parts

An ultrasonic cleaning machine is fitted with two essential portions. They are applicable to all types, forms and applications. It also transcends all functionalities required for it to operate at different frequencies.

- Acoustic wave generators

- A component to hold liquids/ or a cleaning solution

The performance of cleaning depends on the following efficiencies:

- Avoiding damage to the machine while using the pressure/ jet spray.

- Contact between the surface and chemical solutions.

- Pressure application via frequencies.

- Drying after the cleaning process.

Components of the device

The critical ultrasonic cleaning components being discussed are:

- Transducers

- Generators

- Solution for cleaning and tank

- Strainer/Basket

- Cleaning heater

Transducers

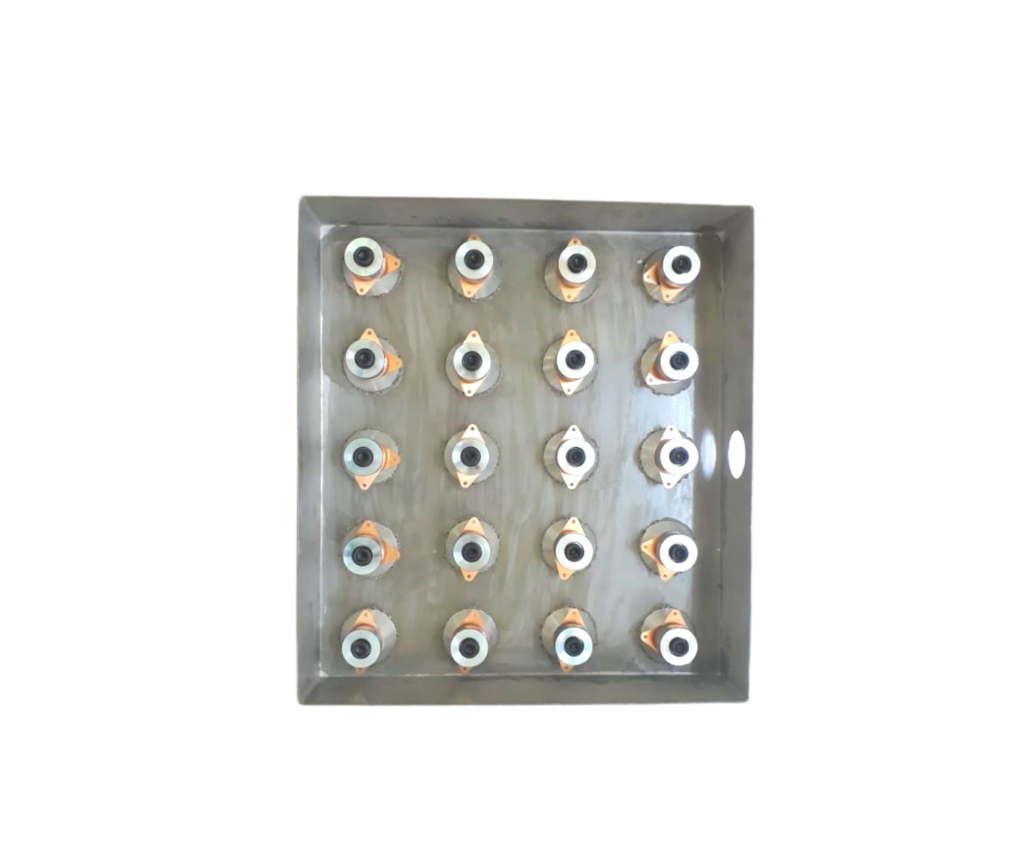

It is a vital component used for converting the energy through mechanical or electrical means. It creates the ultrasonic vibration. They come in two types: piezoelectrical and magnetostrictive. The vibration resulting in the machine is due to one form of energy being converted. Different materials change the geometry when mechanical or electrical means are applied.

Generator

It is a vital part of which receives the power to provide energy with the right frequency to the transducer. Different frequencies are required and power supply has to be adjusted. The kind of contamination that needs to be removed is also taken into consideration. Lower frequencies result in larger bubbles of cavitation. The oscillations are powerful with implosion which do not damage the parts. For small delicate parts high frequency is desirable.

Generators also come with fixed frequencies. The ones having sweeping frequencies solve problems when no cavitation is required.

Cleaning solutions for tank

Transducers are mounted on parts with a tank with the cleaning solution. They are placed on the side or the bottom of the tank. A strong tank will not erode with the pressure put by the cavitation. Tanks made from stainless teel are suitable for this purpose.

Strainer/Basket

A typical ultrasonic machine has components to clean the centre of the machine. Some parts are thicker compared to the cleaning solution. When machines are used it impacts the wall of the tank. If the frequency is low the cleaning process is compromised. Even high waves are capable of causing damage to sensitive parts. Baskets are made with steel mesh to carry the work smoothly.

Cleaning heater

Heat is important and is supplied for assembly heating. It increases the cavitation and intensity. When chemical solutions are used, they do not degrade the materials being cleaned.

Closing thoughts

Any industrial plant requires effective cleaning solutions with the right machines. Removing contamination with ultrasonic cleaning components is critical to keep the environment in a sterile condition. They aid in the manufacturing process where quality is dependent continuously. Unlike manual options ultrasonic cleaning offers the best solutions to polish substrates, sharp corners and inaccessible cavities. All dirt, pollutants, and residues can be cleared with the vacuuming effect.

If you have not yet invested in the energy converting, powerful machines, it is time to do so. Let our experts explain which one will fit your needs.

.png)

.png)

.png)