The construction industry uses concrete due to its durability and strength. It continues to be a low-cost material and its quality differs. Hence, certain buildings are liable to show signs of cracking up after some time. The usage of concrete also depends on the mixing quality, proportions used and curing conditions. Nowadays even the environmental conditions matter. Getting the desired level of performance with specifications and quality is critical. This can be done only with accurate concrete testing machines.

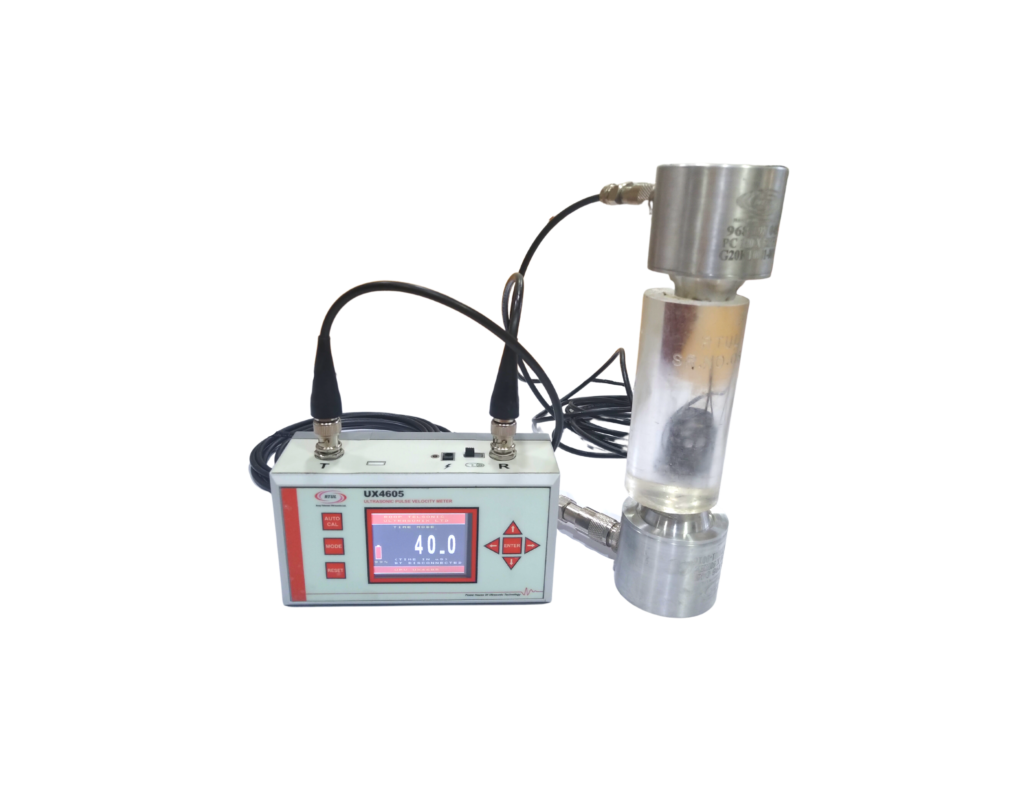

RTUL Group provides an indispensable apparatus for pulse velocity test of concrete. It is essential to use the right machines for testing. Our portfolio also includes thickness gauges, concrete testers and flaw detectors.

Through this informative post we give insights on ultrasonic pulse velocity testing which is a standard requirement for the construction sector. You can reach out to us for detailed discussions on precise measurements and test results.

Five areas of performance of testing equipment

- Fresh concrete

- Sample moulds of concrete

- Concrete mixers

- Strength of concrete

- Cement testing

Non-destructive testing reduces costs

The above performance metrics are monitored so that the concrete can provide structural integrity and load strength. Non-destructive testing (NDT) equipment is designed for quality control and integrity assessment. Inspection teams rely on pulse velocity test of concrete without compromising on the cost or performance of the equipment.

The UPV or the ultrasonic pulse velocity process is widely accepted as a standard globally. Amongst all other NDT processes, it offers the best results as testified by customers. The current techniques use piezoelectric transducers to evaluate the samples.

A fresh mix of concrete requires examination to meet the standards. It includes public pavements made with this mixture. Air meters are used as part of the testing process. The slump test indicates the presence of consistency and workability.

The process for concrete moulds differs as per the shape and size. They are measured for comprehensive strength. They have multiple applications for moulding and need to meet the standards of AASHTO and ASTM. It is important for constriction companies to follow these standard procedures to maintain integrity.

Concrete mixers also need to undergo ultrasonic pulse velocity testing. Samples of asphalt, concrete and cement are checked. The samples are also checked in the labs in different batches. They have diverse requirements and our machines are used for evaluation. The efficiency of our machines provides the right analysis of the testing samples.

This is why our machines are in demand by global companies. The procedures for testing are simple and accurate. They help your technical team to evaluate different specimens.

RTUL Group also offers the following products that can achieve good results.

- Ultrasonic flaw detectors

- Concrete testers

- Pulse receiver

- Custom-made probes

- Reference calibration blocks

- Transducers

- Accessories for machines

As a non-destructive testing unit, the UPV is approved by ASTM standards for any concrete samples. As the results depend on transducers and the coupling quality our machines respond well.

We look forward to associating with you for adding strength to your building materials. Let us know how we can further assist you in selecting the right UPV equipment.

.png)

.png)

.png)