Which is the indispensable apparatus required for concrete testing?

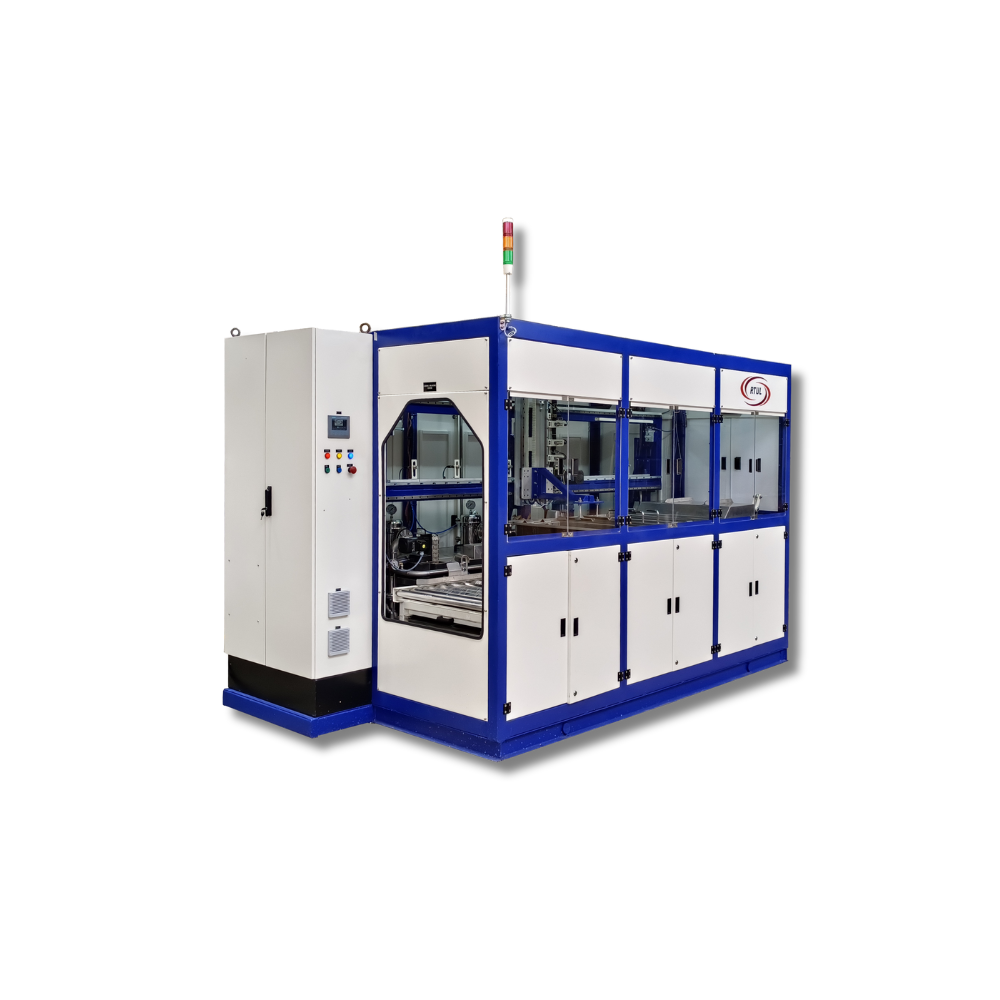

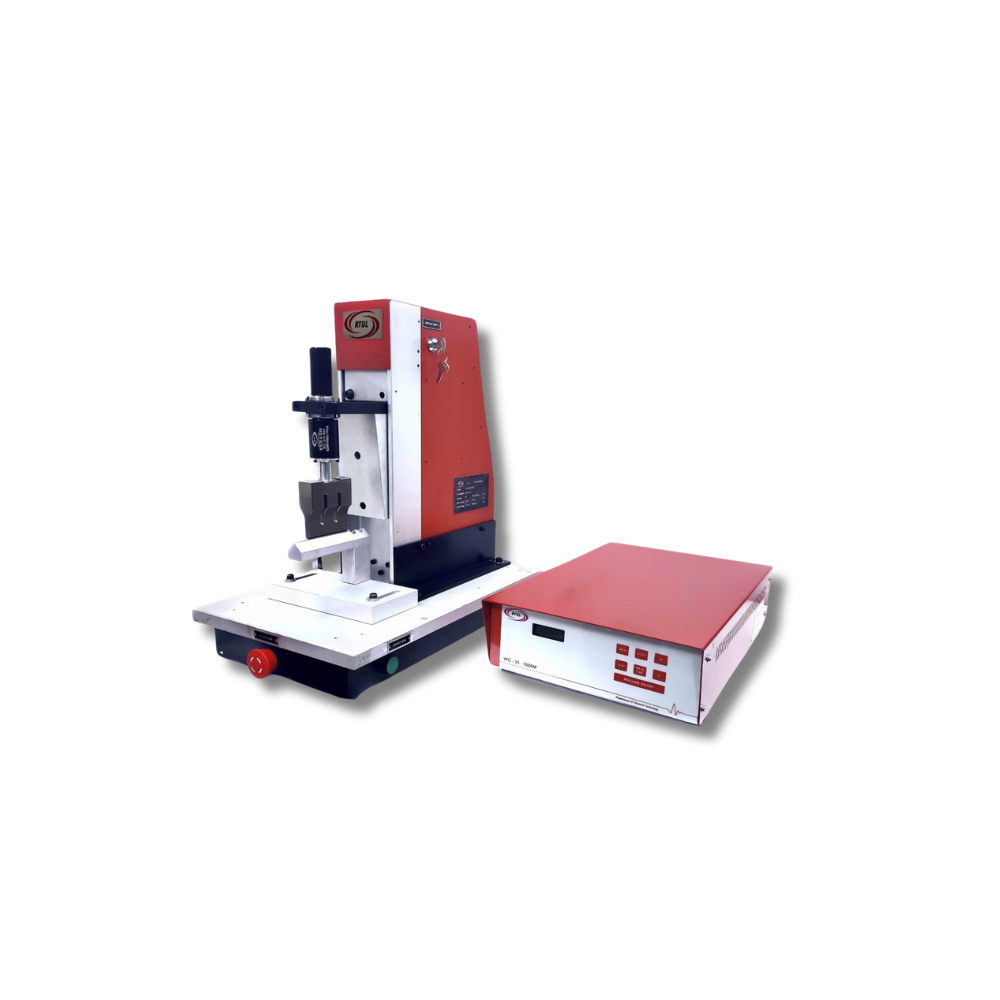

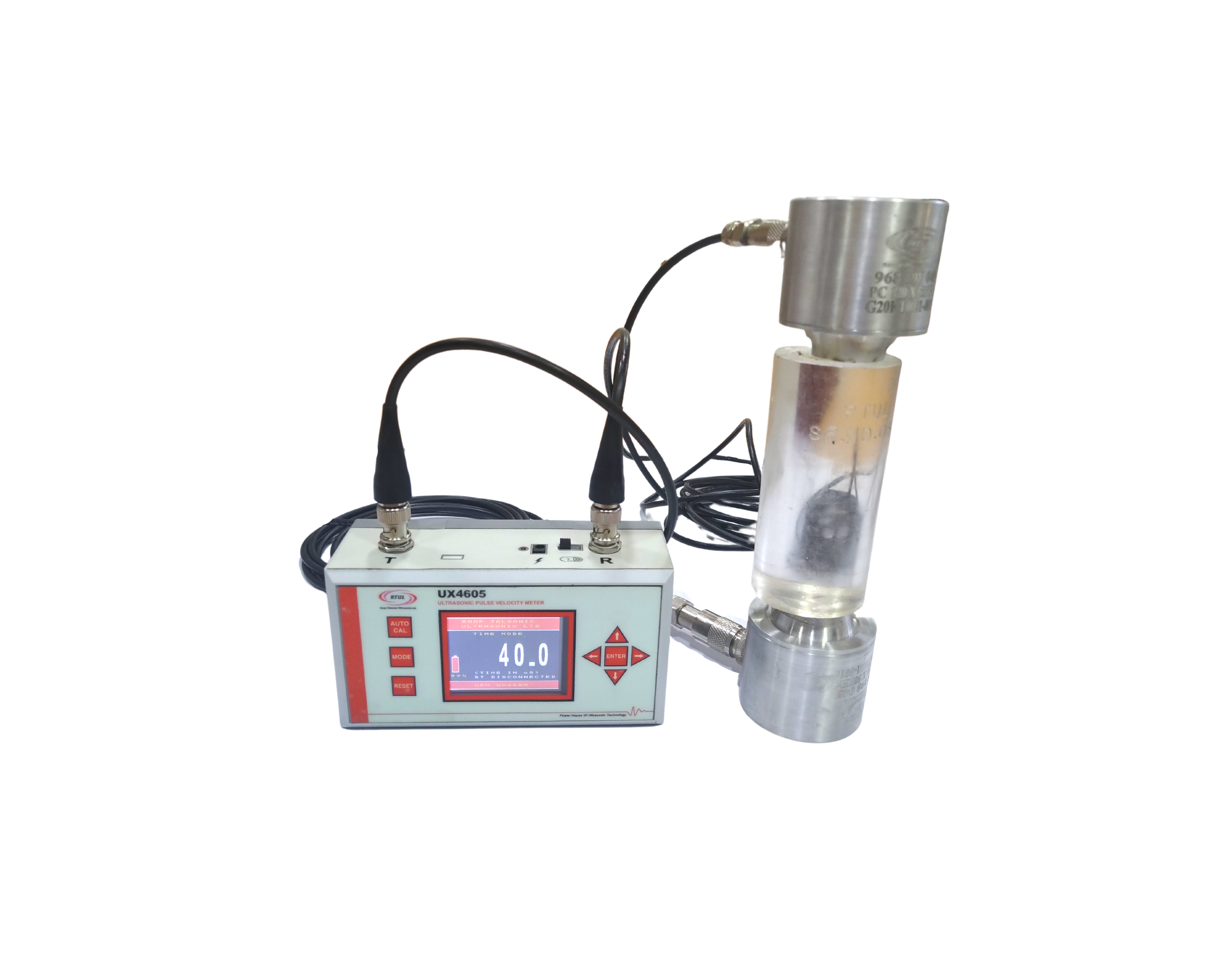

The construction industry uses concrete due to its durability and strength. It continues to be a low-cost material and its quality differs. Hence, certain buildings are liable to show signs of cracking up after some time. The usage of concrete also depends on the mixing quality, proportions used and curing conditions. Nowadays even the environmental conditions matter. Getting the desired level of performance with specifications and quality is critical. This can be done only with accura...

- Read More.png)

.png)

.png)