Why is sonotrode the key-driver for ultrasonic welding in automobile industry?

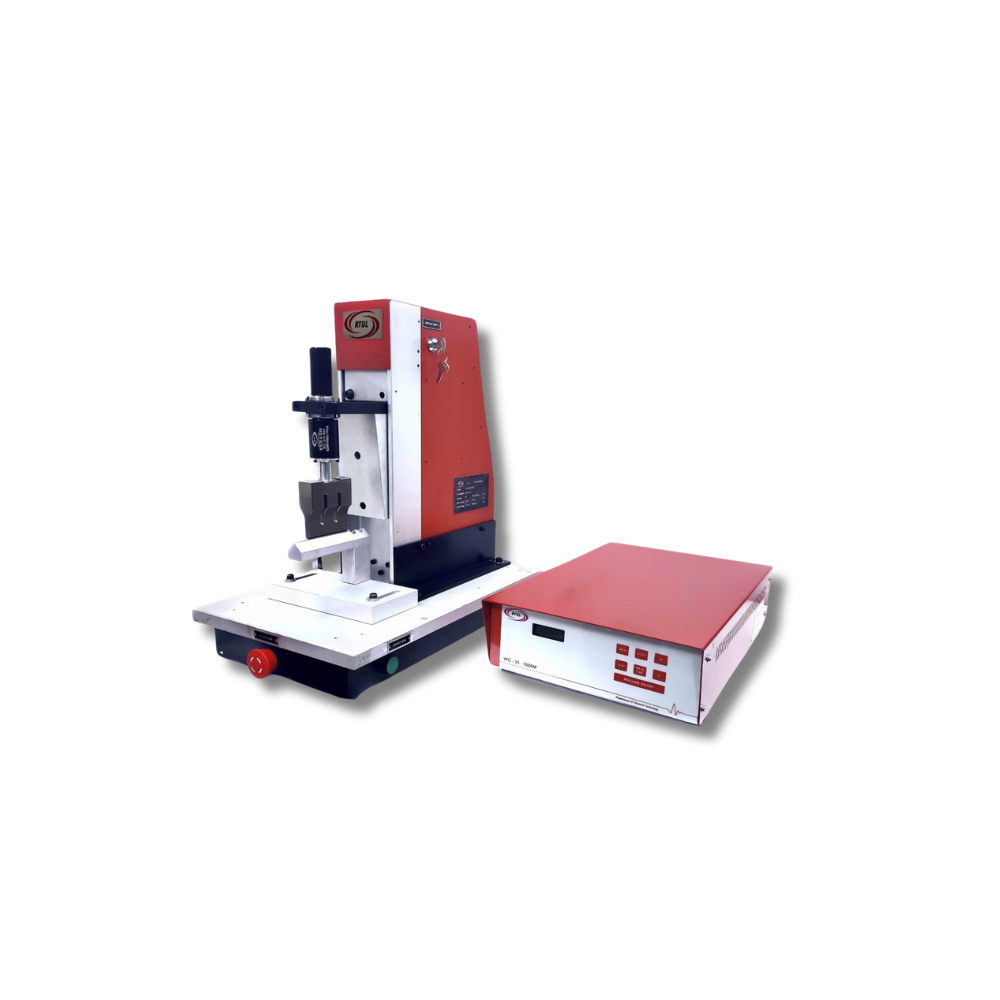

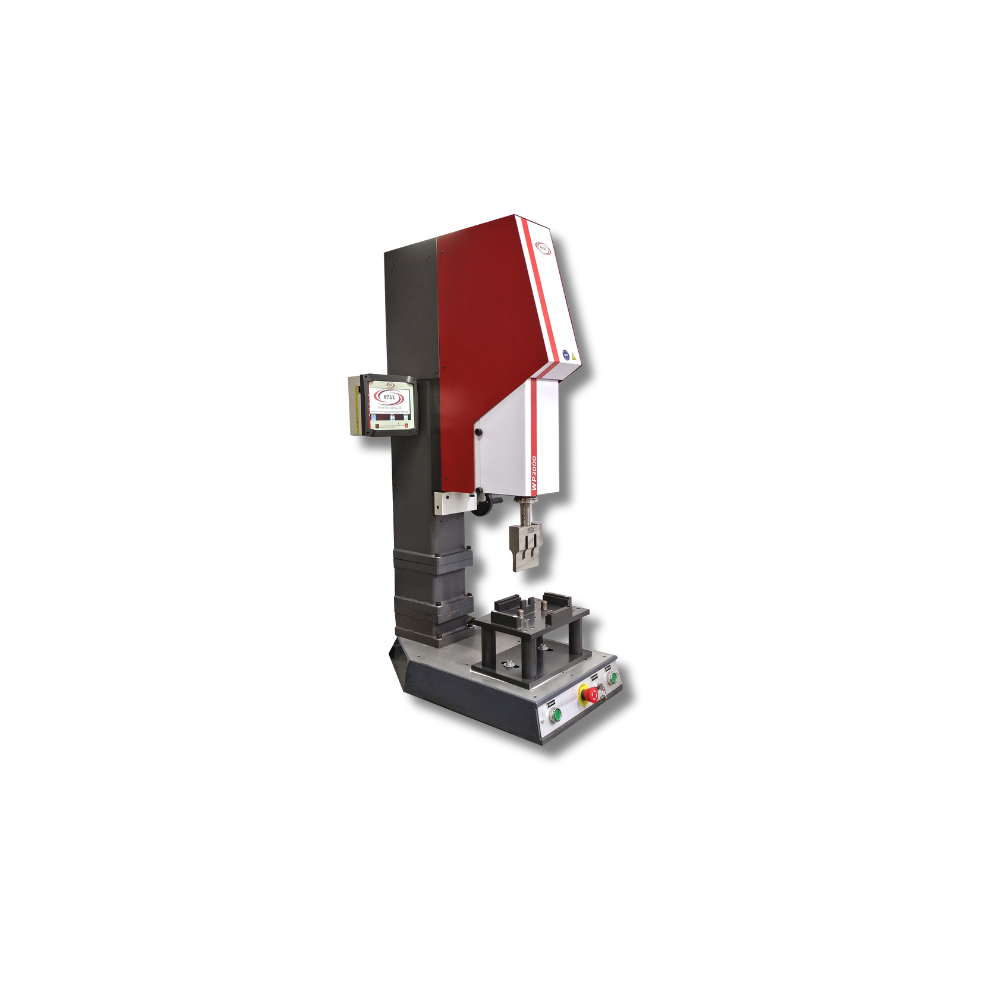

Ever since ultrasonic welding began in the early 1940s, its usage in various applications hasmultiplied. As new materials have cropped up in the market, its industrial practices have increased. It has evolved from the simple high-wave frequency sound to bond materials in the solid state to melt. Bench-top models have valve controls, line voltage, linear encoders and functions for better results. For example, ultrasonic plastic welding is a routine process in the automobile industr...

- Read More.png)

.png)

.png)