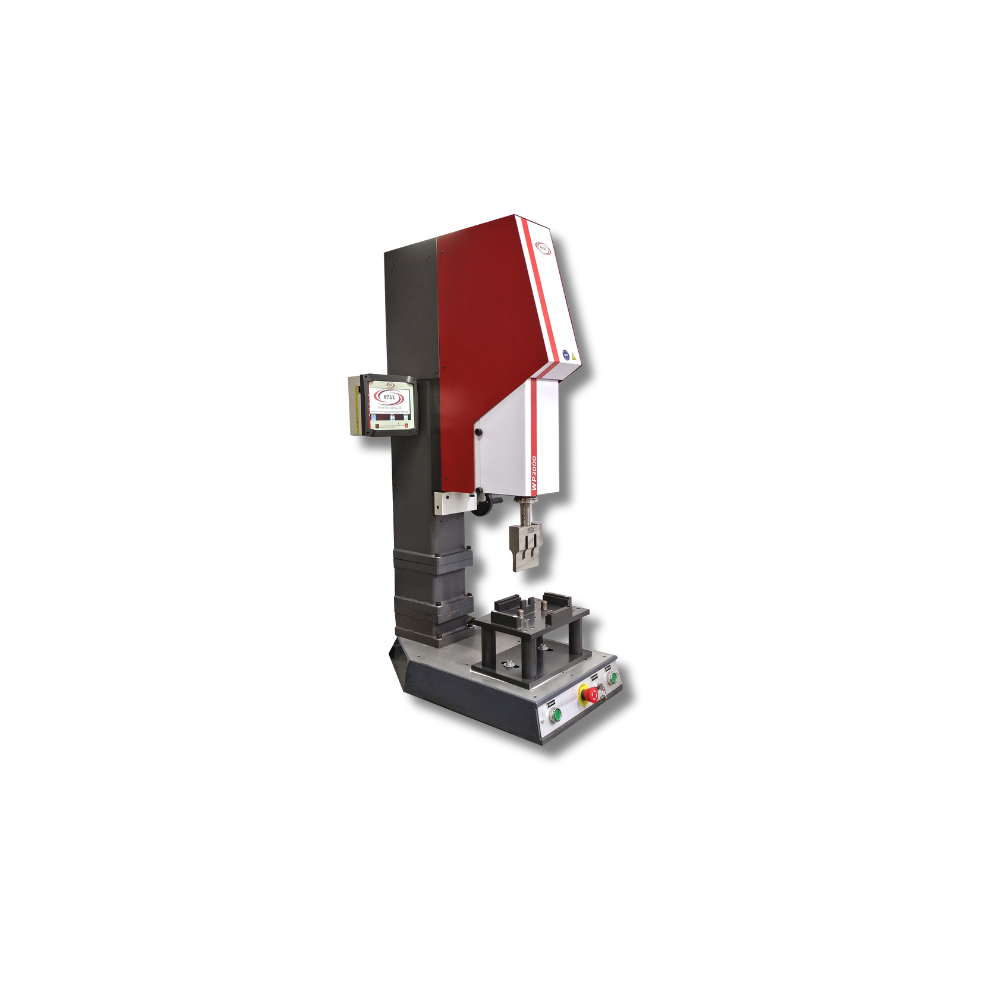

Anatomy of ultrasonic welding machines

An ultrasonic welding machine is operational in diverse industries ranging from medical, packaging, automotive, and aerospace. Its wide applications are feasible in electronic & IT, making it valuable and versatile. To understand its overall utility, we focus on the machines and tools involved to get optimal results. Different techniques are involved to increase its outcome. This guest post features: Why choose an Ultrasonic welding machine? Anatomy of the equipment &...

- Read More.png)

.png)

.png)