Cleaning Blog

Custom Ultrasonic Cleaning Systems

|

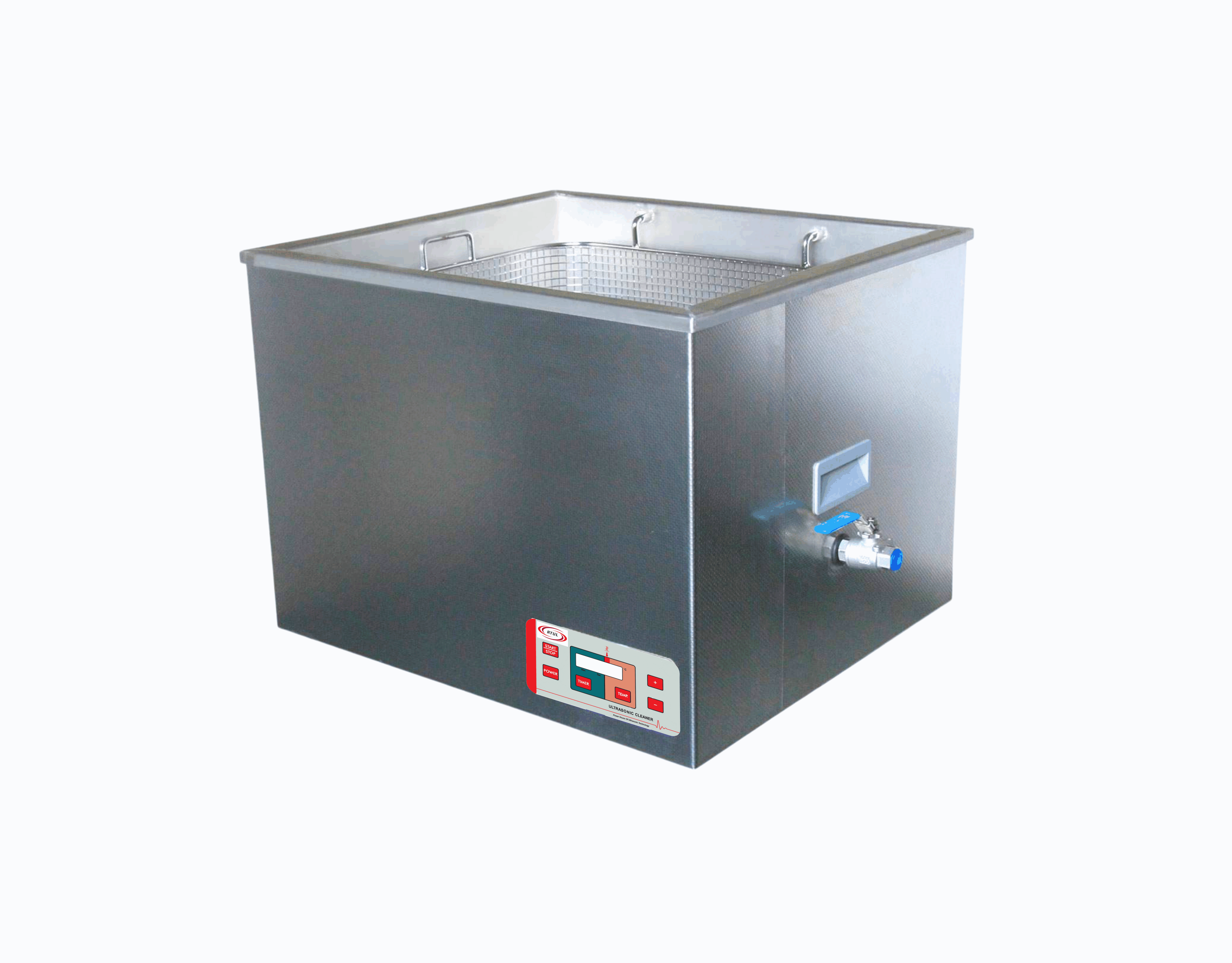

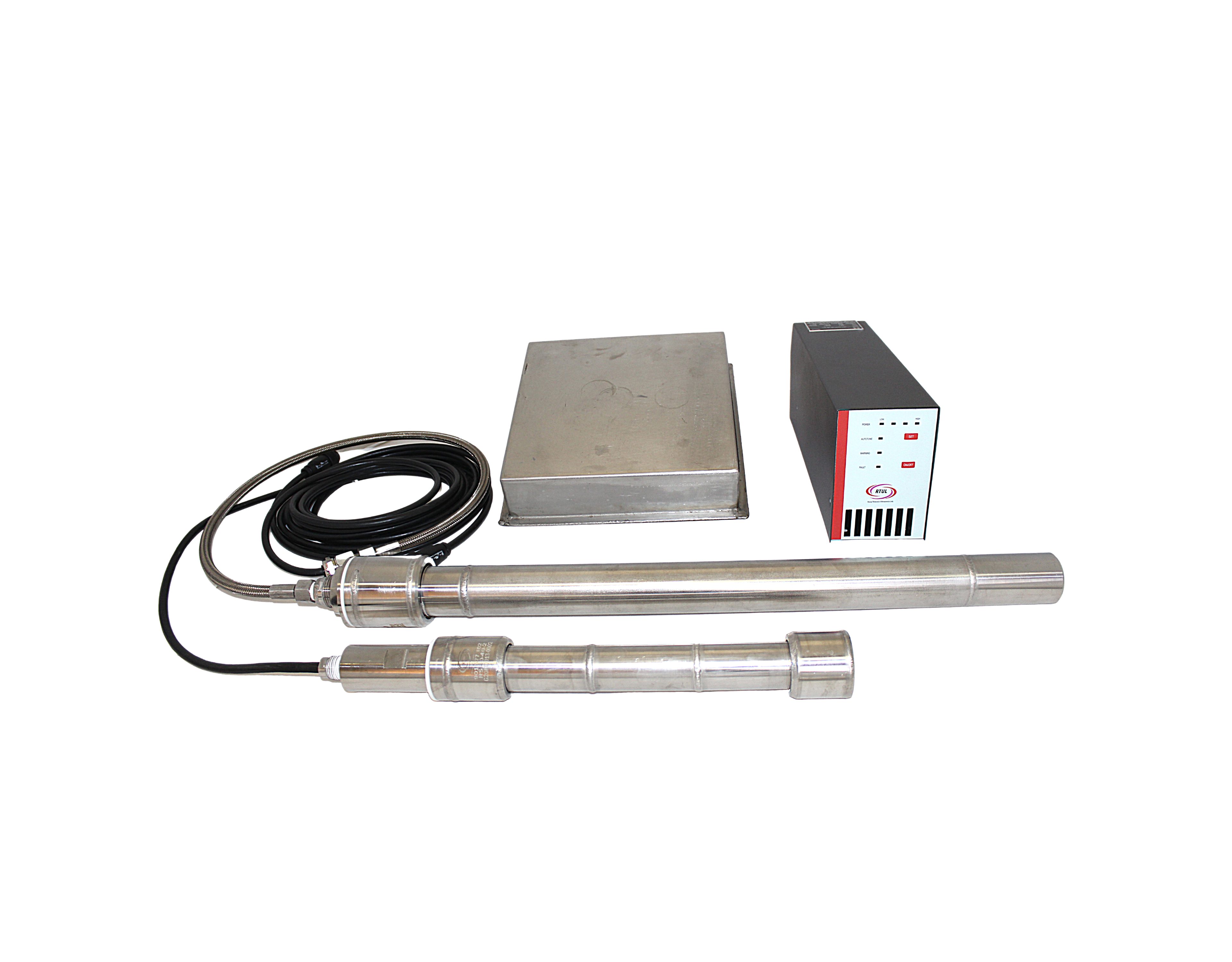

The Task We had to design an Ultrasonic Cleaning machine for cleaning nine different parts using Aqueous solution along with water rinsing prior to drying of component , using hot air drying. |

|

The Solution We provided a 7 stage multichamber cleaning system, out of which 5 stage was for cleaning and rinsing using Aqueous solution, while the other two is for hot air drying. We successfully Particle size of 600 micron.

|

As the volume of production is large 250 litres of tank size was provided. This is one of the largest system provided in North India with minimal time for production.

Advantages

- All the chambers was provided with rotation.

- Consistent Result In Particle Size.

- Leica Micro Scope was used to check the millipore particle size.

- Ultrasonic and heat insulation.

- Sloped floor for complete emptying.

- Edged work area prevents liquid from dropping down.

- Beveled cover guides water condensation back to the tank.

- Protection against dry running for ultrasound and heating.

- Ultrasonic generator is integrated.

- Temperature regulation & Timer for ultrasonic activity.

- Contents of 36, 50, 70, 110, 170, 250 liters.

- Working frequencies 25, 40 kHz.

- Tank, cover, sheathing and drainage tap made of stainless steel.

- Overflow edge with connection (set watertight).

- We also manufacture Industrial ultrasonic cleaners with filtration capability.

.png)

.png)

.png)